中国铆焊制造业的未来前景如何?

介绍性

在全球制造业格局不断变化的今天,中国铆焊制造业作为基础工业的重要组成部分,其发展前景备受关注。本文将分析中国铆焊制造业的现状、挑战和未来发展趋势,为行业从业者和相关投资者提供有价值的参考。

中国铆焊制造业现状分析

行业规模和市场地位

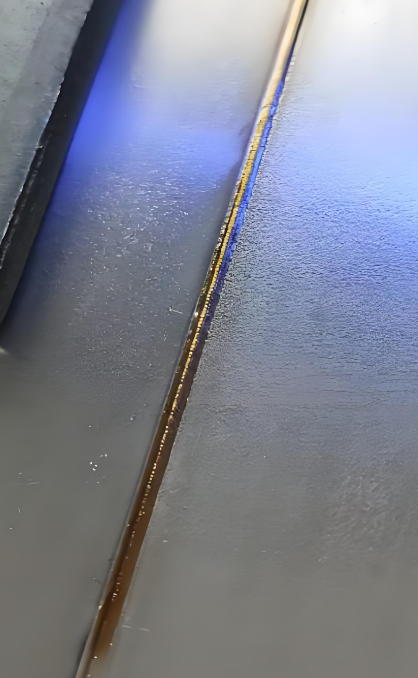

经过几十年的发展,中国的铆接制造业已成为世界上最大的铆接产品生产国和消费国。据统计,中国铆焊工业年产值已超过 1000 亿元,占全球市场份额约 35%。这一庞大的产业基础为中国制造业提供了坚实的支撑![图片[1]-中国铆焊制造业的未来前景如何(全球制造业格局不断变化的今天,中国铆焊制造业作为基础工业的重要组成部分) - cndlfh.com-cndlfh.com](https://cndlfh.com/wp-content/uploads/2025/06/QQ20250625-204231.png)

最新技术

目前,中国的铆焊制造业呈现出 "金字塔 "式的技术分布:

上一页: 少数几家领先企业掌握了自动化和智能焊接技术

中央:大多数公司使用半自动化生产设备

底部:一些中小微企业仍依赖传统手工焊接

主要应用领域

铆钉焊接技术得到广泛应用:

建筑(钢结构、桥梁等)

汽车制造(车身焊接)

造船业

压力锅

航天

城域网

中国铆焊制造业面临的挑战

劳动力成本上升

随着中国人口红利的逐渐消失,熟练焊工短缺的问题日益突出。持续上升的劳动力成本压缩了企业的利润空间,迫使该行业向自动化转型。

国际竞争加剧

东南亚国家以较低的劳动力成本吸引外资,而发达国家则通过技术创新保持高端市场优势,我国铆焊制造业正面临 "前后夹击 "的竞争态势。

环境保护压力增大

传统焊接工艺产生的废气、焊渣和噪声污染面临着越来越严格的环保法规和限制,企业的环保投资成本也随之增加![图片[2]-中国铆焊制造业的未来前景如何(全球制造业格局不断变化的今天,中国铆焊制造业作为基础工业的重要组成部分) - cndlfh.com-cndlfh.com](https://cndlfh.com/wp-content/uploads/2025/06/QQ20250625-204151-800x406.png)

原材料价格波动

钢材等原材料价格的不稳定直接影响到铆焊企业的生产成本和利润水平。

中国铆焊制造业的未来发展趋势

自动化和智能转型

未来 5-10 年,中国铆焊制造业将加速向自动化、智能化发展:

焊接机器人普及率将大幅提高

自动优化工艺参数的智能焊接系统

将数字孪生技术应用于焊接过程模拟和监测

新材料和新工艺的应用

随着新材料的不断涌现,铆接技术将面临新的机遇和挑战:

研究和开发轻质材料(如高强度钢和铝合金)的焊接工艺

推广和应用激光焊接、搅拌摩擦焊接和其他新工艺

异质材料连接技术的突破

绿色制造与可持续发展

环保要求推动了行业的绿色转型:

开发低烟尘、低能耗焊接工艺

焊接废料回收技术

焊接生产中的清洁能源

服务型制造模式的兴起

从传统的生产型制造向服务型制造转变:

提供焊接解决方案而非单一产品

远程监控和预测性维护服务

焊接数据价值挖掘与应用

政策支持和市场机遇

国家政策指导

"中国制造2025 "战略将智能制造作为主攻方向,为铆足产业转型升级提供政策支持:

智能制造专项资金支持

促进技术改造的税收激励措施

高新技术企业认定

"一带一路 "倡议带来的市场机遇

基础设施的连通性创造了巨大的市场需求:

海外项目对焊接的需求不断增长

中国焊接设备和技术的出口机会

国际能力合作的新空间

拓展新兴领域的应用

新能源、电动汽车、海洋工程等新兴领域为铆接技术创造了新的应用场景:

动力电池焊接技术

海上风电钢材焊接

储氢罐焊接

结论和建议

未来展望

综上所述,中国铆焊制造业未来发展前景广阔,但也存在挑战。预计到 2030 年

行业将完成自动化转型,智能化水平将显著提高

龙头企业的国际竞争力进一步增强

中高端市场份额继续扩大

绿色制造成为行业标准

企业发展建议

增加研发投资:重点关注自动化设备和新焊接工艺的研发

培养复合型劳动力:同时具备焊接和数字技能的劳动力

拓展服务价值链:从单纯的加工向整体解决方案提供商转型

海外市场:抓住 "一带一路 "机遇,实现国际化发展

我国铆焊制造业正处于转型升级的关键时期,那些能够把握技术发展趋势、积极应对挑战的企业将在未来的市场竞争中占据有利地位,共同推动我国焊接从 "焊接大国 "向 "焊接强国 "迈进。

暂无评论内容