Optimization plan for wire cutting aluminum materials

When aluminum materials are processed by wire cutting, the conductive blocks wear out at an alarming and rapid rate, causing many operators to encounter difficult problems. This situation not only affects the processing efficiency, but also drives up production costs.

Special challenges in machining aluminum

Aluminum is widely used in electrical appliance manufacturing and conductive parts manufacturing due to its good electrical conductivity and lightweight properties. When the structure of these parts is complex and has subtle features, conventional machining is difficult, and wire cutting becomes the first choice. However, the physical and chemical properties of aluminum bring unique problems to the wire-cutting process . The conductive block of wire-cut aluminum parts wears out , such as difficulty in chip removal and the easy generation of aluminum oxide hard particles. These are the root causes of increased wear.

During processing, aluminum chips and electrical corrosion products tend to adhere to small molybdenum wire or copper wire electrodes. These attachments are brought to the contact point of the conductive block with the movement of the electrode wire, thereby forming a grinding effect. At the same time, the hardness of the alumina particles produced by aluminum at high temperatures is higher, which further accelerates the wear of the surface of the conductive block, and grooves will be worn out in a short time.

Direct consequences of conductive block wear

If the conductive block is greatly worn, this situation may cause poor contact between it and the electrode wire, which will lead to wear of the conductive block during wire discharge spark cutting of aluminum parts . This will not only damage the surface of the electrode wire, but may also cause instantaneous current fluctuations, which will affect the stability of the discharge energy. The direct consequence is reduced processing accuracy, as well as stripes appearing on the surface of the workpiece or roughness that does not meet standards. There are many problems.

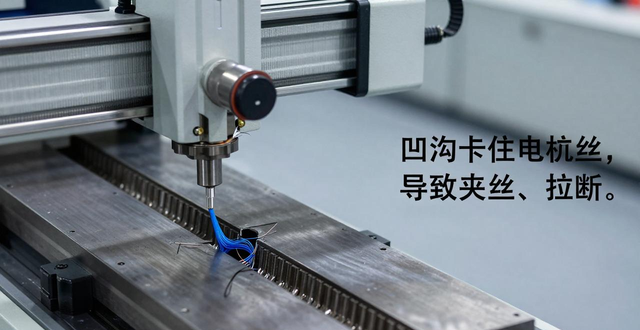

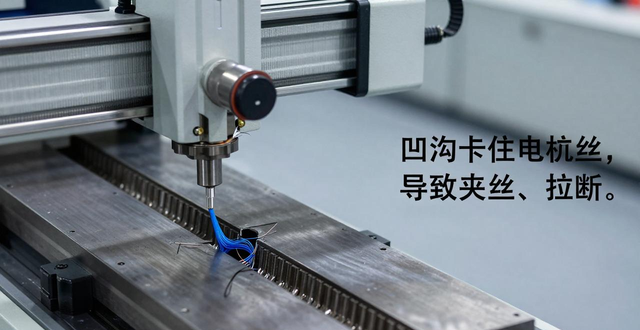

What’s more serious is that the groove may get stuck in the running electrode wire, eventually causing “wire clamping” or even pulling the electrode wire off. The broken electrode wire means that the processing will be interrupted, which will require re-threading and tool setting operations, which will waste a lot of time that could be used. For batch processing or precision mold manufacturing, this is not a pre-planned shutdown situation and will have a great impact on the production schedule.

Key adjustments to electrical parameters

In order to deal with the wear and tear that occurs during aluminum processing, the first measure to be taken is to adjust the electrical parameters of wire-cut aluminum parts for wear of the conductive block. The pulse width can be appropriately reduced. When the energy of a single pulse decreases, the amount of metal removed by each discharge will be reduced, and the alumina particles produced will become smaller and smaller. This can effectively reduce the scratch wear of the conductive block.

At the same time, the pulse interval time should be relatively increased. A longer interval can allow the working fluid to fully flush, thereby taking away aluminum chips and electrical corrosion products from the gap, thereby improving chip removal conditions. This can reduce the chance of aluminum chips adhering to the electrode wire and maintain a stable cutting process, thereby indirectly protecting the conductive block.

Working fluid concentration and cooling lubrication

The most important thing is the selection and concentration of the working fluid. When processing aluminum, it is recommended to increase the concentration of the common emulsion solution from the conventional 1:10 to about 1:8. The higher-concentration working fluid has better detergency and lubricity. It can more effectively wrap and take away small aluminum chips, preventing them from gathering in the processing area and forming a viscous colloid.

A higher concentration of working fluid can form a more stable protective film on the surface of the electrode wire, thereby reducing the direct adhesion of electrical corrosion products. The working fluid with good cooling effect can control the temperature rise of the electrode wire and the workpiece, thereby inhibiting the large-scale production of hard aluminum oxide film and reducing the source of wear particles from the root.

Auxiliary machinery improvement measures

Adding a wear-resistant sponge or special rubber pad between the conductive block and the support is a practical mechanical improvement method. This measure can absorb part of the vibration during the operation of the electrode wire, thereby making the contact between the electrode wire and the conductive block softer and smoother, thereby reducing impact wear. At the same time, the pad material can prevent some splashed impurities from directly impacting the conductive block.

It is also very necessary to manually clean the contact area of the conductive block regularly. When processing thick aluminum parts, or when processing for a long time, you can set it to pause in the middle and use a non-metal scraper blade to clean the accumulated attachments on the surface of the conductive block. For machine tools with a high degree of automation, the electrode wire can be programmed to automatically offset a certain distance at regular intervals for wire cutting processing of aluminum materials, so that the electrode wire can contact different parts of the conductive block and evenly utilize its entire working surface.

Preventive maintenance and operating habits

Establishing a preventive maintenance plan for aluminum processing can shorten the inspection and replacement cycle of conductive blocks. For example, when processing ordinary steel, conductive blocks can be used for several months, while when processing aluminum, they should be inspected every month. Record the wear data of conductive blocks under different aluminum grades and workpieces of different thicknesses, explore relevant patterns, and prepare spare parts in advance.

Personnel responsible for operations must develop good process preparation practices. When programming, for thick and large aluminum parts, it is reasonable to introduce a multi-cutting process. For the first time, use greater energy to cut quickly, and then use refinement parameters to continue. Doing so can improve the chip evacuation situation. Before wire cutting, proper surface cleaning should be performed on the aluminum billet to completely remove oil stains and oxide layers. This can also reduce irregular discharges and the appearance of impurities during the processing.

As far as you are concerned, during the processing of aluminum alloy or other sticky materials, what particularly unique equipment wear problems have you encountered, and how did you use clever methods to solve them? Welcome to share your experience in the comment area? If you think this article is of practical value, please like it and share it with more people in the same industry.

暂无评论内容