Fine blanking multi-station pier head forming of three-dimensional complex parts

In industrial production, in order to create three-dimensional metal parts with exquisite structures and diverse functions, the traditional single stamping process has become insufficient for riveting and welding processing . This has promoted the rapid development of multi-station composite forming technology.

Core concepts of fine blanking composite forming

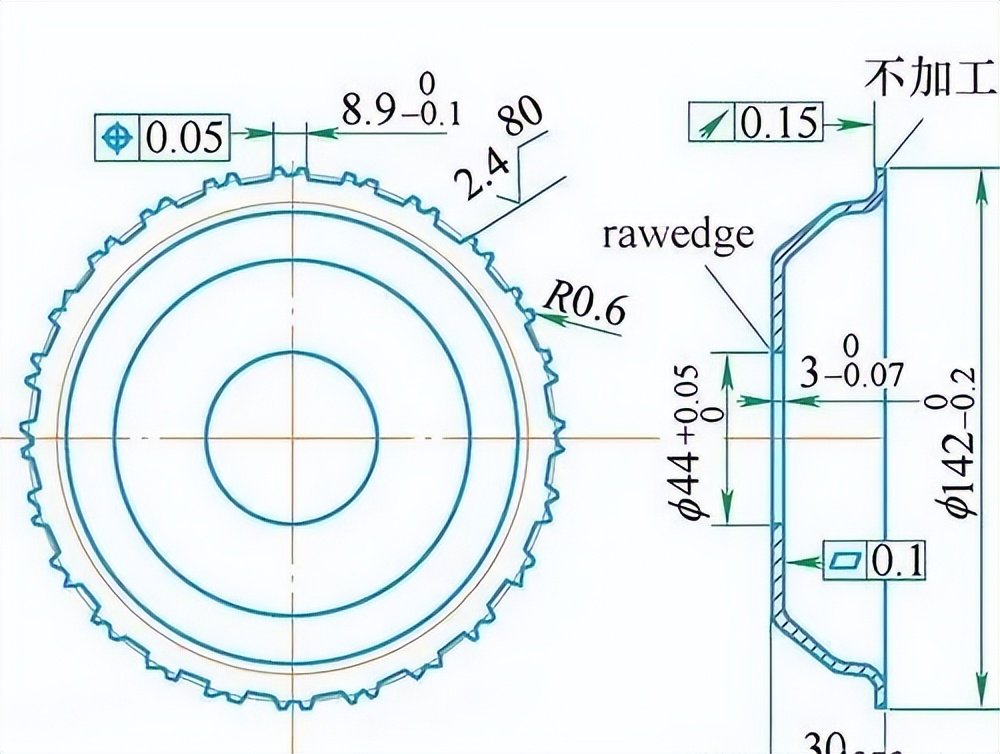

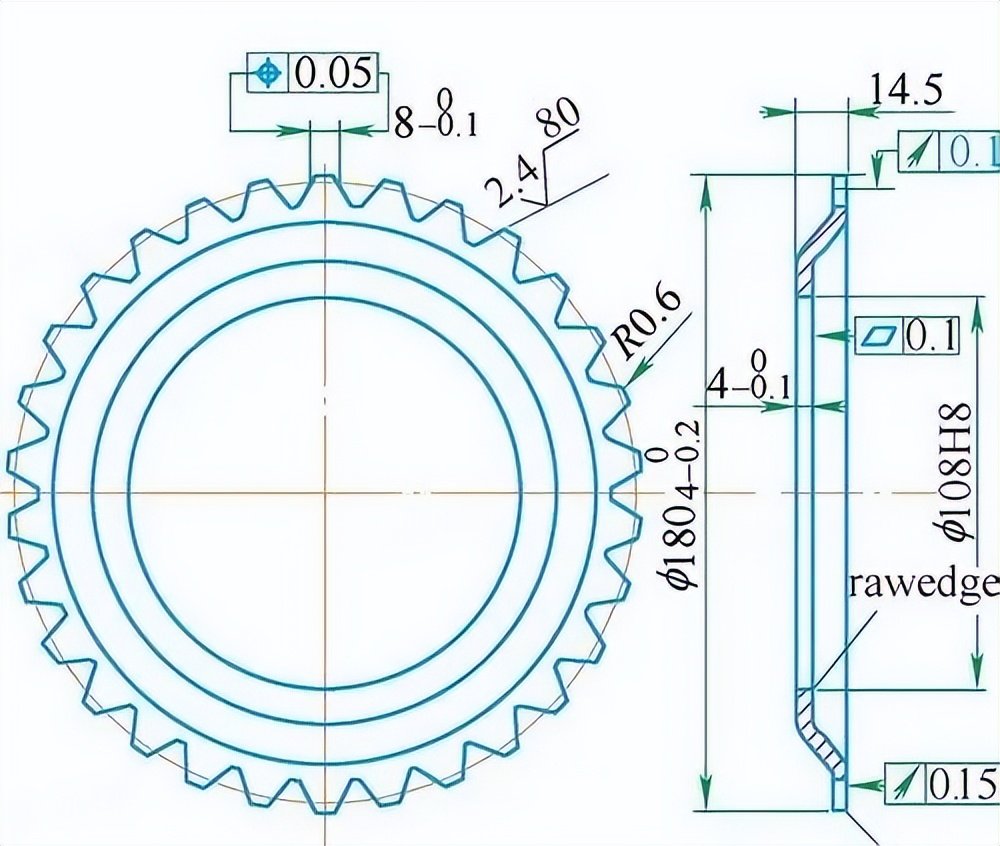

It is not a single process of fine blanking composite forming, but a deep combination of fine blanking and other sheet metal forming processes through progressive dies. It can orderly integrate multiple steps such as punching, bending, and drawing into a set of molds to continuously complete such a process. For example, the contours and local features of some sprockets and connecting rods in cars often rely on this integrated solution to achieve efficient molding.

Its core advantage is reflected in the enhanced production efficiency and part accuracy. Since multiple processes are carried out consecutively in the same mold, it reduces the need for complicated repositioning when switching between different equipment. This not only speeds up the production pace, but also better ensures the relative position accuracy between each forming feature, which is critical for complex three-dimensional parts.

From a two-dimensional plane to a three-dimensional plane

Traditional fine blanking, which is mainly used to produce flat plate parts of equal thickness, belongs to the category of two-dimensional processing. However, composite forming technology breaks this limitation and allows products to be expanded to highly variable three-dimensional parts, such as dish gears with bosses or counterbore holes in gearboxes, structural parts, etc., all of which rely on this technology to achieve three-dimensional forming.

This leap has greatly broadened the boundaries of fine blanking technology. It makes fine blanking no longer limited to simple contour separation, but can be directly manufactured to produce three-dimensional functional parts with assembly or transmission functions, realizing the role change from “blanking” to “forming manufacturing”.

Combination with volumetric forming process

When parts have higher requirements, fine blanking can be combined with volumetric forming processes. This situation is related to methods such as upsetting and extrusion that redistribute the material volume. These methods are used to manufacture parts with unequal thickness or partial protrusions. For example, a deep blind hole or boss is directly extruded on a thick steel plate. This is a typical fine blanking-extrusion composite forming method, right?

This combination puts forward higher requirements for equipment and also puts forward higher requirements for molds. The extrusion process requires huge force to make the material plastically flow, so a fineblanking machine with sufficient tonnage must be used. At the same time, the mold structure is more complex, and the filling of materials needs to be accurately controlled, as well as the flow direction of the material to avoid defects.

Multi-station automatic cold heading technology

Multi-station automatic cold heading is another high-efficiency composite forming process for axially symmetrical parts such as bolts and nuts. It integrates many work stations such as shearing, upsetting, forming, and diameter reduction on one piece of equipment. The rods are continuously fed in and gradually deformed through each station before finally forming the product. Modern cold heading machines can have 5 or more work stations.

![图片[4]-Fine Blanking Multi-station Pier Head Forming Of Three-dimensional Complex Parts-Dalian Fuhong Machinery Co., Ltd](https://endlfh.com/wp-content/uploads/2025/12/1767180218290_3.jpg)

With virtually no waste, this process offers extremely high material utilization and part strength is enhanced by work hardening. The output can reach hundreds of pieces per minute, and its production speed is extremely fast. The blank pretreatment and mold cooling and lubrication during production have strict specifications to ensure accuracy.

Key conditions for process implementation

To successfully implement composite forming processes, high-performance presses are indispensable. The equipment must provide a large and stable forming force, precise slide control and good rigidity. For example, when performing deep extrusion operations, fineblanking machines with a tonnage of 800 tons or more are often required.

The core carrier of the process is the fine-blanking multi-station pier forming of three-dimensional complex parts of the mold. The design of the multi-station progressive die or composite die is very critical. It is necessary to reasonably arrange the station sequence and design an effective material guidance and positioning mechanism. At the same time, surface treatment such as phosphating and saponification of the blank to reduce friction and prevent mold sticking is an important link to ensure continuous and stable production.

Application prospects and challenges

This technology has broad prospects in the fields of automobiles, electrical appliances, and precision instruments. As part design becomes increasingly complex and lightweight, the need for one-time molding of complex three-dimensional parts will continue to rise. It can significantly reduce subsequent processing and reduce overall costs, which is in line with the development trend of high efficiency and precision in modern manufacturing.

However, there are challenges in promoting technology. Mold design and manufacturing is very difficult, the cycle is very long, the cost is very high, and it is highly dependent on the experience of technical personnel. At the same time, process debugging is complex and requires a large number of tests on different materials and shapes to determine the best parameters, which places high demands on the company’s R&D capabilities.

What is the general method of riveting and welding for companies that want to improve their integrated parts manufacturing capabilities? Do you think the biggest bottleneck when introducing composite forming technology is the high investment in equipment, or the lack of professionals who are proficient in process and mold design? Welcome to share your views.

暂无评论内容