numerical control työstöMachining with Boring Machines: The Core Force Driving the Development of High Precision in Modern Manufacturing![图片[1]-CNC Machining and Boring: The Core Force Driving High-Precision Development in Modern Manufacturing-Dalian Fuhong Machinery Co., Ltd](https://endlfh.com/wp-content/uploads/2025/10/QQ20251001-210002.png)

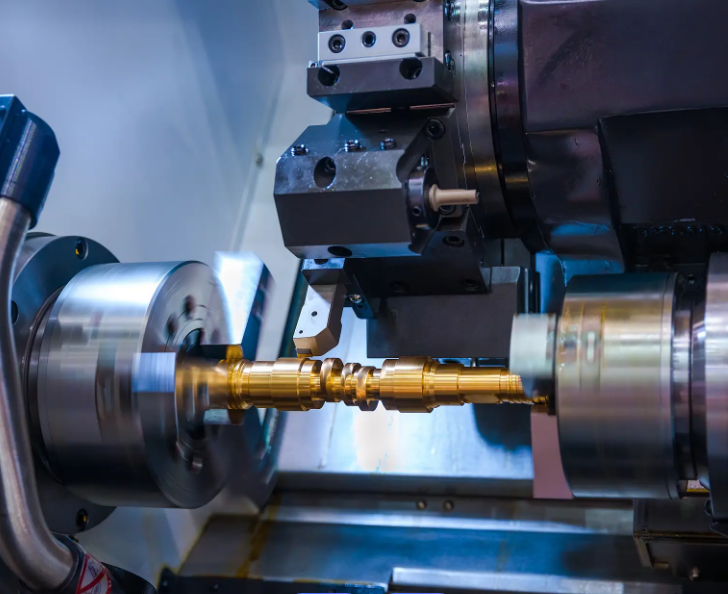

Against the backdrop of global manufacturing transformation towards intelligence and precision, thenumerical control machiningWith its high efficiency and precision, it has become a key technology to promote industrial upgrading; andboring machineAs a CNC machining system specialising in complex holes and large workpieces in the core process, but also for high-end manufacturing areas to solve many technical problems. In this paper, we will comprehensively analyse the technical principles of CNC machining and boring machine processing, core advantages, typical application scenarios, and at the same time for enterprises to choose the processing services to provide practical guidance to help enterprises in the fierce competition in the market to seize the first opportunity.

I. CNC machining: reshaping manufacturing efficiency and precision “all-rounder”

1. Definition and technical principles of CNC machining

CNC Machining is a modern technology that automatically completes the machining of workpieces with the help of a computer numerical control system (CNC system), which provides precise control of the machine tool’s trajectory and cutting parameters (e.g., rotational speed, feed, and depth of cut). The core logic is to convert the design drawings into digital programs, through the program instructions to drive the relative motion of the machine tool and the workpiece, to achieve automation and standardisation of production from raw materials to finished products. Compared with traditional manual machining, CNC machining gets rid of the excessive reliance on manual operation experience, and fundamentally improves the stability and consistency of machining.

2. Four core advantages of CNC machining

Ultra-high precision for demanding needsCNC machining has a repeatable positioning accuracy of ±0.001mm, enabling the accurate machining of precision parts that meet the requirements of aerospace, medical devices and other fields. For example, in automotive engine spool machining, CNC machining can control the dimensional error within a very small range to ensure the efficient operation of the engine.

Efficient production and reduced time costsCNC machining equipment can be used 24 hours a day without frequent human intervention, thanks to its automated mode of operation. Compared with traditional machine tools, its productivity can be increased by 3-5 times, and at the same time, it reduces the waste of materials caused by manual operation errors, and controls the scrap rate within 5%, which significantly reduces the long-term production cost of the enterprise.

Flexible production to suit the needs of multiple categoriesThe same CNC machine can be quickly switched to process different types of workpieces by simply modifying the CNC programme, without the need for large-scale adjustments to the machine structure. This flexible quality is especially suitable for small batch, multi-species customised production, such as industrial moulds, special parts processing, to help enterprises quickly respond to changes in market demand.

Safety and stability to ensure production continuity: Modern CNC systems are equipped with perfect safety protection functions, including overload protection, emergency stop, tool collision warning, etc.. These functions can effectively avoid equipment damage and safety accidents in the machining process, reduce the pressure of safety management in the workshop, and ensure the stable operation of the production process.

Two,boring machine: “Masters of precision” specialising in complex hole systems.

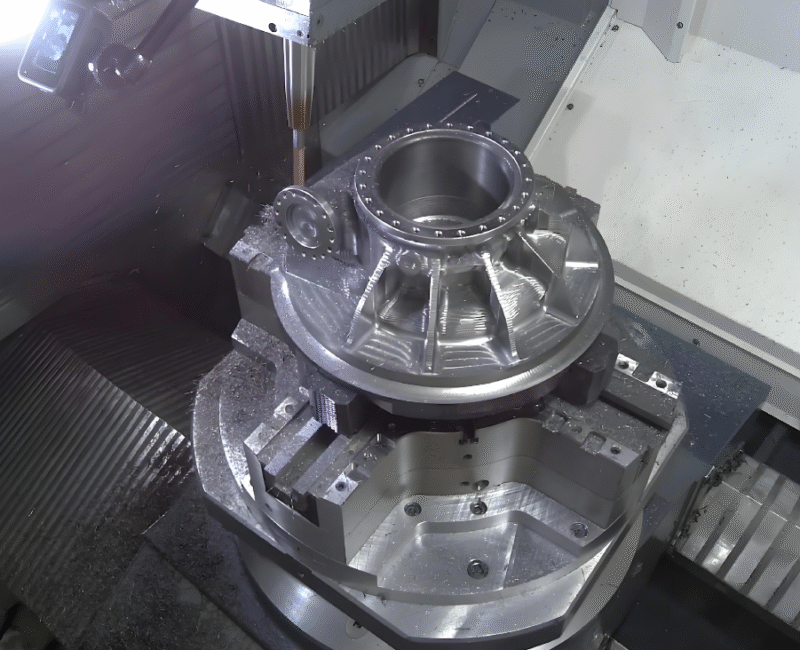

1. Technical orientation and application scenarios of boring machine machining

Boring machine machining is an important branch of CNC machining, mainly for theComplex hole systems, large box-type workpieces, shaped structural partsCarry out machining. Its core function is to complete high-precision hole machining such as deep holes, step holes, threaded holes and other holes through the rotary cutting of the boring tool and the accurate feeding of the spindle, while taking into account the milling operation of the plane and inclined surfaces. In the field of large equipment manufacturing, such as machine tool bed, engine block, engineering machinery chassis parts processing, boring machine processing by virtue of “one-stop solution for multiple holes processing and overall structural moulding” advantage, become indispensable to the key process.![图片[2]-CNC Machining and Boring: The Core Force Driving High-Precision Development in Modern Manufacturing-Dalian Fuhong Machinery Co., Ltd](https://endlfh.com/wp-content/uploads/2025/06/QQ20250627-201124-800x668.png)

2. Key Technical Highlights of Boring Machines

Excellent hole system machining accuracyThe closed-loop servo control system can control the coaxiality and parallelism of holes within 0.005mm, which perfectly solves the problem of “accumulation of deviation in multiple holes” in traditional processing. In the aero-engine magazine, hydraulic valve body and other parts that require extremely high precision of the hole system, the accuracy advantage of boring machine processing is particularly prominent.

High load capacity, suitable for large workpieces.The CNC boring machines are of different types, such as floor-standing and horizontal, with a table load capacity of several tonnes, capable of easily machining large workpieces with a length of more than 3 metres and a weight of several tonnes. During the machining process, the workpieces do not need to be clamped frequently, effectively reducing the errors brought about by multiple positioning and guaranteeing the machining accuracy of large workpieces.

Composite processing to shorten the production processModern CNC boring machines are commonly integrated with milling, drilling, tapping and other functions, which can complete the whole process of “hole machining + plane milling + contour forming” of the workpiece at one time. This composite processing capability to avoid the loss of precision caused by the workpiece in the transfer between multiple devices, while significantly shortening the production cycle and improve the overall production efficiency.

Intelligent upgrades for improved processing stabilityHigh-end CNC boring machines are equipped with probe inspection system, which can measure the workpiece machining dimensions in real time and automatically compensate the machining errors according to the measurement results, further improving the machining accuracy. In addition, some of the equipment supports direct connection of CAD/CAM software, realising the seamless connection of “design drawing – machining procedure – production execution”, reducing manual intervention and lowering the probability of errors.

Third, CNC machining and boring machine processing application scenarios comparison and synergistic

Although CNC machining and boring machines have their own focuses, they often work in tandem in actual production to cover the needs of machining from small precision parts to large complex components. The following table clearly shows the differences and synergies between the two in different areas of application:

Areas of application

Characteristics of processing requirements

CNC machining applications

Boring Machine Machining Applications

Synergy Advantage

aerospace

Special materials (titanium alloys, high-temperature alloys), complex structures (space curved surfaces, multiple holes)

5-axis CNC machining centre for surface forming and precision milling

CNC boring machine processing deep holes, step holes, to ensure the accuracy of the hole system

Achieve “surface + hole system” integrated machining of complex parts to meet the requirements of aerospace-grade precision.

automobile manufacturing

Large batch sizes and high degree of standardisation (engine blocks, gearbox housings)

CNC lathe and milling machine to complete the cylindrical and flat surface machining of batch parts

CNC Boring Line Completes Multi-Hole System for Cylinder Blocks and Housings

Formation of automated production lines, taking into account the efficiency of mass production and the accuracy of the hole system to meet the needs of mass production in the automotive industry.

medical equipment

High precision requirements, special materials (titanium artificial joints, stainless steel surgical instruments)

CNC machining centre completes artificial joint surface grinding, instrument contour machining

CNC boring machine to complete the precision hole processing of surgical instruments, to ensure the safety of use

Meet the dual requirements of “high precision + biocompatibility” for medical devices and enhance product reliability.

Mould Manufacturing

Large workpiece size and complex cavities (automotive bumper moulds, home appliance shell moulds)

High-speed CNC milling machine to complete the mould cavity roughing, semi-finishing processing

CNC boring machine to complete the finishing of the mould guide pillar holes, positioning holes, to ensure the accuracy of the mould assembly

Shorten the mould development cycle, enhance the service life of the mould and reduce the production cost of the enterprise.

A Practical Guide for Enterprises Choosing CNC Machining and Boring Service Providers

Choosing a reliable processing service provider is the key to guaranteeing product quality and controlling production costs. Enterprises can focus on the following four dimensions in the screening process:

Equipment and Technical StrengthPriority is given to service providers equipped with high-end equipment, such as machining equipment equipped with CNC systems of famous brands such as Siemens of Germany and Fanuc of Japan, as well as companies with five-axis machining centres and large CNC boring machines. At the same time, understand whether the service provider has experience in processing difficult-to-machine materials (such as titanium alloys and high-temperature alloys) to ensure that their technical capabilities match their needs.

Quality Control SystemCheck whether the service provider has passed the ISO9001 quality management system certification, and for special areas such as automotive, aerospace, etc., you also need to confirm whether it has industry certifications such as IATF16949 and AS9100. In addition, understand the service provider’s testing equipment configuration, such as coordinate measuring machine, laser interferometer, etc., to ensure that the processing accuracy can be traced and verified.

Project Cases and Industry Reputation: Through the service provider’s official website, industry platforms and other channels, check its past cooperation cases, especially the cooperation experience with enterprises in the same industry. At the same time, refer to customer reviews, years of cooperation and other information to judge the service stability and reputation of the service provider. If the service provider has provided processing services for well-known enterprises, its technology and service capabilities are usually more secure.

Customisation and responsivenessFor non-standard parts processing needs, you need to confirm whether the service provider has a professional programming team, can quickly develop processing solutions and generate processing procedures based on the design drawings. In addition, to understand the service provider’s order response speed and delivery capacity, such as whether to support the urgent order of 72 hours of rapid prototyping, whether to meet the enterprise’s production cycle requirements.

V. Future Trends in CNC Machining and Boring Machining

With the continuous penetration of Industry 4.0 technology, CNC machining and boring machines are moving towards a smarter, more efficient and greener direction:

Intelligent level continues to improveIn the future, the CNC system will integrate artificial intelligence (AI) technology to achieve adaptive adjustment of machining parameters – according to the hardness of the material, tool wear state automatically optimise the cutting speed and feed, reduce tool loss, improve processing efficiency. At the same time, digital twin technology will be widely used in boring machine processing, through virtual simulation to simulate the machining process, to find out the process problems in advance and reduce the cost of trial and error.

Green Processing Becomes New DirectionIn response to the global call for environmental protection, CNC machining equipment will adopt more energy-efficient drive systems and cooling technology to reduce energy consumption and cutting fluid waste. In addition, the development and application of new environmentally friendly cutting materials will further reduce the environmental pollution of the machining process, and promote the manufacturing industry to the direction of green and sustainable development.

Accelerated cross-sectoral integrationCNC machining and boring machine processing will be deeply integrated with 3D printing, industrial robotics and other technologies to form an integrated production model of “additive manufacturing + subtractive machining + automated assembly”. This integration mode can give full play to the advantages of each technology, providing more efficient and flexible solutions for the manufacture of complex parts.

VI. Conclusion

numerical control machiningtogether withboring machineAs the core technology of modern manufacturing, it is not only the key to improve product precision and production efficiency, but also an important support for enterprises to achieve industrial upgrading and participate in global competition. Whether it is the high-precision parts in the aerospace field or the batch standardised components in the automotive industry, the synergistic empowerment of these two technologies is indispensable.

If your company has CNC machining or boring needs, why not contact us — we have an experienced technical team, equipped with many high-end CNC equipment, can provide the whole process from drawing analysis, process design to mass production services. We will be professional technology, strict quality control and efficient response speed, help your products stand out in the market competition, and jointly promote the high-quality development of the manufacturing industry

暂无评论内容