The calculation of high-strength bolts and embedded parts connecting steel beams and concrete columns only considers shear resistance, which is unsafe.

You should never think that if the steel beams and concrete columns are articulated, the nodes will really be able to rotate freely. When the steel beam is very large, such as when the height exceeds 600 millimeters or even worse, a considerable bending moment will actually occur at the end of the beam where the bolts are tightened. If only shear force is considered during design, and bolts and embedded parts are calculated as purely sheared parts, then this node will bury hidden dangers during construction or use. Calculation of high-strength bolts and embedded parts connecting steel beams and concrete columns only considers shear resistance, which is unsafe. In the past, there have been accidents at many construction sites in which embedded parts were directly pulled out.

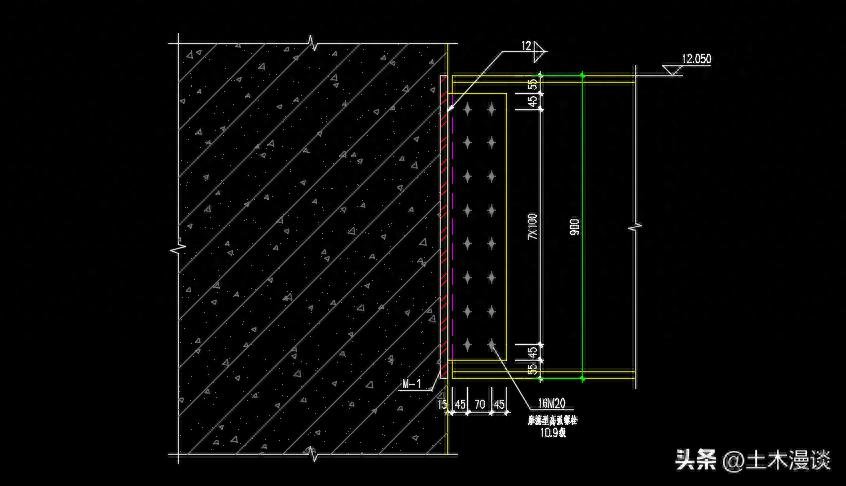

The real stress state of high beam hinges

Nodes with hinged properties will not transmit bending moments under the assumptions of the design. However, in actual situations, high-strength bolts tightly screw the webs and connecting plates of the steel beams together. When the beam is subjected to load and then bends and deforms, the bolts in the upper and lower areas of the web show completely different forces. The upper half of the bolts bear tension, and the lower half of the bolts bear pressure. This forms a couple that can resist bending moments.

This actual bending moment is directly related to the cross-section height of the beam. Even if a steel beam with a height of 800 mm is designed in a hinged manner, the secondary bending moment generated by its end restraints may reach 15% to 20% of the main bending moment. If this bending moment is ignored, it is equivalent to ignoring the horizontal tension acting on the bolt group and embedded parts.

![图片[1]-The Calculation Of High-strength Bolts And Embedded Parts Connecting Steel Beams And Concrete Columns Only Considers Shear Resistance, Which Is Unsafe.-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1771690573403_0.jpg)

Realistic interpretation of normative provisions

![图片[2]-The Calculation Of High-strength Bolts And Embedded Parts Connecting Steel Beams And Concrete Columns Only Considers Shear Resistance, Which Is Unsafe.-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1771690573403_1.png)

Article 8.1.2 of the "Technical Regulations for Steel Structures of High-Rise Civil Buildings" JGJ99-2015 is actually very clear. It requires distinguishing the bending area and shear area of the web. When many colleagues looked at the specifications for riveting and welding embedded steel beams in conjunction with civil construction , they only remembered the word "articulated", but did not pay attention to the specific requirements for bolt arrangement and bearing capacity calculation.

Article 8.2.5 directly points out the key points of riveting and welding of embedded steel beams in conjunction with civil construction . It requires that the number of bolts be calculated separately for the area that bears bending moment and the area that bears shear force. The specification writing team has long considered the situation of sorghum and specifically pointed out that the minimum value should be selected based on different damage modes. This so-called "minimum value" does not require you to cut corners, but requires you to fully calculate the bending moment and shear forces.

Misunderstandings in the design of bolt groups

A common approach is to arrange the bolts evenly in several rows, and then simply divide the total shear force by the number of bolts to get the shear force experienced by each bolt. However, this algorithm is completely ineffective in high beam nodes. The reason is that the bending moment at the beam end will cause the bolt force distribution to be extremely uneven. Therefore, the actual tensile force endured by the top row of bolts may be several times higher than the average value.

The correct approach is to first determine the height of the compression zone of the web, and then to determine the height of the tension zone of the web. Generally, the neutral axis of the bolt group can be determined at the center of the pressure zone of the web. Then calculate the tensile force borne by the bolt in the tension zone, and then combine the shear force to check the anti-slip and tensile bearing capacity of the bolt. These two effects need to be superimposed and considered.

The dual functions of embedded anchor bars

The design of embedded parts constitutes the most significant risk of this type of joint. Many drawings only provide a shear key. The anchor bars are several steel bars configured according to pure shear components and are riveted and welded to the steel beam embedded parts in conjunction with civil construction . However, once the bending moment at the beam end is generated, the embedded parts actually bear both shear force and tension force, which is a state of composite tension and shear stress.

Under such a stressed state, the bearing capacity of the anchor bar will be greatly reduced. The current "Code for Design of Concrete Structures" clearly gives the strength reduction formula of anchor bars when they are under tension-shear composite stress conditions. If the area of anchor bars is calculated only based on shear resistance, but the effect of tension is ignored, the actual number of reinforcements may be only half of the requirement or even less. This is the fundamental reason why pull-out accidents occur frequently.

Weak links in the construction process

![图片[3]-The Calculation Of High-strength Bolts And Embedded Parts Connecting Steel Beams And Concrete Columns Only Considers Shear Resistance, Which Is Unsafe.-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1771690573403_2.png)

During the construction phase, it is often the most dangerous period for such nodes. During this period, after the concrete is poured but its strength has not yet increased, the steel beams must be hoisted to be in place. At this time, if secondary beams or other components begin to apply load, the bolts and embedded parts will have to bear the load generated during the entire construction phase. However, the anchoring strength of the concrete at this time may only reach 70% of the design value.

If the steel beam during the hoisting process is subjected to lateral force, experienced constructors have discovered that the concrete around the embedded parts is prone to micro cracks. Once these cracks occur, the holding force of the anchor bars will decrease. When loading is carried out when it is officially put into use, the joints will already be working in a sick state.

More reliable node approach

If conditions permit, it would be a wiser choice to place the steel beam directly on the top of the column or on the corbels. The stress path of this pressure-bearing node is the most direct. The pressure borne by the steel beam is transferred to the concrete through the contact surface, and the shear force is all borne by the shear key or bolt. The result is that there is almost no space at the end of the beam that can produce bending moments, and its safety is also greatly improved.

In Shanghai, there is a super high-rise project. During the construction of the project, due to the large cross-section size of the steel beams, the originally designed side hinges were changed to a column top resting method. Since then, not only has the speed of construction and installation been increased, but the improvement has reached 30%. Next, the results of subsequent structural inspections have confirmed that the working status of the nodes is fully in line with the design expectations, and the strain value of the embedded parts is smaller than the value calculated theoretically.

Have you ever encountered a situation where the supervisor questioned such nodes during construction drawing review or at the construction site? How was it resolved at that time? Welcome to share your handling experience in the comment area. If you think this article is helpful to you, please like it and forward it to more peers.

暂无评论内容