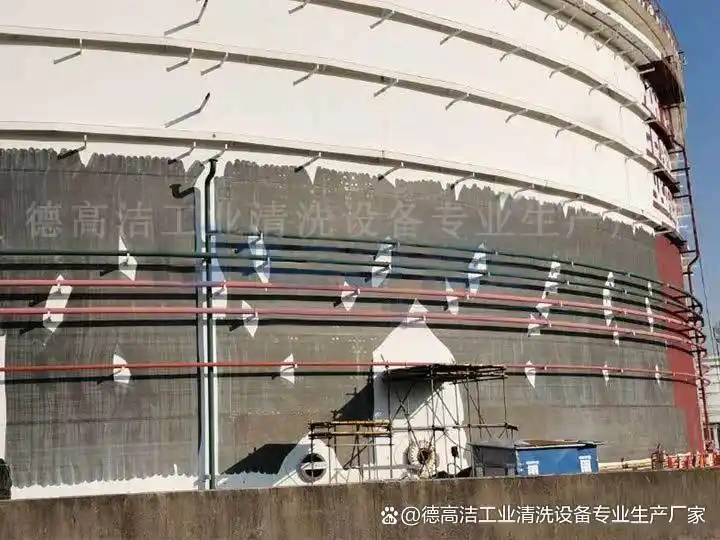

Anti-corrosion construction of the outer wall of vertical storage tanks: a real case of rust removal and spraying construction of wall-climbing robot storage tanks

In chemical plants, anti-corrosion construction for the outer walls of giant storage tanks that often reach tens of thousands of cubic meters has always been an extremely difficult problem. The traditional method not only consumes time and money, but also requires workers to risk working at heights. However, now, the emergence of wall-climbing robots is completely changing this situation.

Pain points of traditional construction

![图片[1]-Anti-corrosion Construction Of The Outer Wall Of Vertical Storage Tanks: A Real Case Of Rust Removal And Spraying Construction Of Wall-climbing Robot Storage Tanks-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770999707835_0.webp)

When anti-corrosion of storage tanks, erecting scaffolding is the most common method, but its price is not small. Take a 50,000-meter storage tank as an example. Its diameter is 60 meters and the tank wall height is 19.37 meters. At this time, nearly 3,800 square meters of double-row scaffolding need to be set up. Calculated based on the 2009 maintenance quota, the erection and disassembly alone requires 370 working days, which is equivalent to 20 people working for 18 and a half days.

Although high-altitude hanging panels save a lot of effort in building shelves, the requirements for personnel qualifications are extremely high. Workers are suspended from the tank wall dozens of meters high, which not only puts them under great psychological pressure, but also affects their work efficiency accordingly. Both methods face the same problems: long construction period, high labor costs, and high safety risks.

Wall-climbing robot appears

It is not for other reasons that the wall-climbing robot is adsorbed on the storage tank, but because of magnetic adsorption technology to achieve this effect. It has the ability to walk steadily on vertical walls, even walls at negative angles. Its four-wheel drive method allows it to perform anti-corrosion construction on the outer walls of vertical storage tanks during the movement process: a real case of wall-climbing robot tank rust removal and spraying construction, which can not only maintain stable paint and anti-corrosion on the inner and outer walls of large tanks after riveting and welding , but also has the characteristics of flexibility. When encountering the curved surface structure of the storage tank or the convex terrain at the weld, it can also easily cross over without getting stuck.

![图片[2]-Anti-corrosion Construction Of The Outer Wall Of Vertical Storage Tanks: A Real Case Of Rust Removal And Spraying Construction Of Wall-climbing Robot Storage Tanks-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770999707835_1.png)

The load capacity of this robot is indeed considerable, and it can carry equipment weighing 150 to 200 kilograms to carry out operations. This means that whether it is a rust removal cleaner or a spraying device, they can all be hung up for work. Workers only need to stand on the ground and hold the remote control to operate, thus completely saying goodbye to the risks of working at heights.

![图片[3]-Anti-corrosion Construction Of The Outer Wall Of Vertical Storage Tanks: A Real Case Of Rust Removal And Spraying Construction Of Wall-climbing Robot Storage Tanks-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770999707835_2.webp)

Practical cases of rust and paint removal

During a certain period of construction to remove rust stains from the outer wall of the storage tank, the wall-climbing robot was equipped with a device for removing rust stains and cleaning with ultra-high-pressure water. The robot moves closely against the tank wall, and the high-pressure water instantly peels off rust stains and old paint layers. At the same time, it collects the waste water and waste residue generated at the bottom of the equipment. There is no flying dust that can be seen on site.

The rust removal efficiency of this machine reaches the range of fifty to seventy square meters per hour, which is much faster than manual work. More importantly, its rust removal quality is guaranteed and can reach the Sa2.5 level standard. The surface appears clean. After the large tank is riveted and welded, the inner and outer walls are spray-painted for anti-corrosion , and rust will not appear quickly. There is no pollution in the entire operation process, which is quite environmentally friendly and meets the current strict environmental protection requirements.

Spraying to new heights

![图片[4]-Anti-corrosion Construction Of The Outer Wall Of Vertical Storage Tanks: A Real Case Of Rust Removal And Spraying Construction Of Wall-climbing Robot Storage Tanks-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770999707835_3.webp)

Manual labor can be replaced by wall-climbing robots during spraying construction, which is also feasible. The mechanized spraying path is more stable than manual spraying, and the thickness of the paint surface is uniform, and there will be no inconsistent thickness. Moreover, the robot will not get tired and can work continuously for a long time, so the efficiency must be high.

What is even more intelligent is that this robot used for spraying can be equipped with a paint film thickness gauge. While spraying, it can detect the thickness of the paint film in real time. The detected data will be directly transmitted back to the relevant location. With the help of the monitoring platform carried by the robot itself, the operator can clearly see the picture displayed during spraying and can make adjustments to relevant parameters at any time to ensure construction quality.

Safety and cost win-win

![图片[5]-Anti-corrosion Construction Of The Outer Wall Of Vertical Storage Tanks: A Real Case Of Rust Removal And Spraying Construction Of Wall-climbing Robot Storage Tanks-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770999707835_4.png)

From a safety perspective, wall-climbing robots have the most significant advantages. Workers do not need to climb high again. Operating on the ground can eliminate the risk of falling from high places. Enterprises do not have to worry about downtime losses and personal injury compensation issues caused by safety accidents, and the pressure on safety management will be greatly reduced.

In terms of cost, the inner and outer walls of large tanks are spray-painted and anti-corrosion after riveting and welding . Although there will be an investment in purchasing equipment at the beginning, as long as you do long-term calculations, you will find that it will be more cost-effective. The huge labor costs and material costs required during the erection and dismantling of the scaffolding are saved, and the construction period is shortened, which means that the storage tank can be put into use faster. In addition, the quality of robot construction is stable and the probability of rework is low. The overall benefits are very considerable.

Future application prospects

The scale of chemical equipment is increasing day by day, and the size of storage tanks continues to set new records. It is increasingly difficult for manual construction to adapt to this situation. The advantages of robots will become more and more obvious. Rust removal and spraying are just the beginning. In the future, wall-climbing robots can be used for flaw detection, cleaning and maintenance.

![图片[6]-Anti-corrosion Construction Of The Outer Wall Of Vertical Storage Tanks: A Real Case Of Rust Removal And Spraying Construction Of Wall-climbing Robot Storage Tanks-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770999707835_5.webp)

Technology continues to advance, such as lighter materials, smarter path planning, and more precise operation control. It can be foreseen that in a few years wall-climbing robots will become a standard configuration for storage tank maintenance, just like forklifts are indispensable in every chemical plant today.

In the factory you are in, have you ever thought about introducing this kind of wall-climbing robot to replace traditional high-altitude operations? Welcome to share your opinions and experiences in the comment area, and give it a like so that more people can see this practical technology.

暂无评论内容