Solutions to the easy-to-break wires of wire-cut aluminum parts

During wire cutting processing, the conductive blocks of wire-cut aluminum parts are worn and wire breakage occurs frequently. This not only slows down the progress, but also directly increases the production cost. Among them, problems with the management of the conductive block are often the main hidden cause of wire breakage.

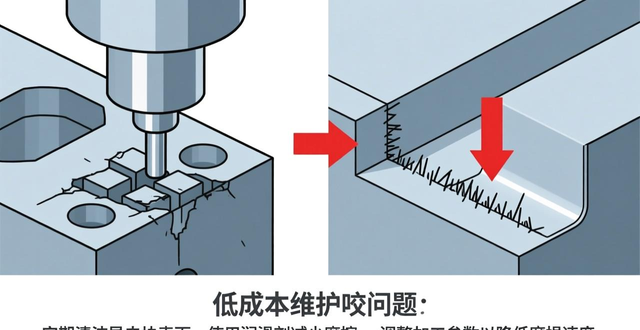

The groove of the conductive block causes wire breakage

After long-term friction with the high-speed running molybdenum wire, grooves will gradually form on the surface of the conductive block. The edges of these grooves are uneven and smooth, and it is very easy to get the molybdenum wire stuck. The molybdenum wire will be pinched off under the action of tension. Once the wire is broken, the processing will have to be interrupted and the wire threading operation will be performed, which seriously reduces the utilization rate of the machine tool.

The consequences of such a situation are not limited to shutdown. The processed surface around the broken wire point will become rough due to repeated cutting, which will affect the surface quality of the workpiece. As far as precious materials are concerned, every broken wire means that a section of material is wasted, which virtually increases the cost of a single piece.

Adjust the position of the upper and lower conductive blocks

The direct way to solve the problem is to regularly adjust the contact area between the conductive block and the molybdenum wire. The conductive blocks of the upper wire rack and the lower wire rack need to be included in the adjustment plan. When operating, first loosen the fixing screw and slightly rotate the conductive block along its axis at an angle so that the unworn arc surface contacts the molybdenum wire.

![图片[1]-Solutions To The Easy-to-break Wires Of Wire-cut Aluminum Parts-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/01/1768738311554_0.png)

By changing the contact point, the molybdenum wire no longer wears through the conductive block of wire-cut aluminum parts in the original deep groove, and the friction state is refreshed. This can effectively prevent the "wire biting" phenomenon caused by burrs on the edge of the groove. A simple position adjustment solution to the easily broken wire of wire-cut aluminum parts avoids frequent replacement of new conductive blocks, which is the key to low-cost maintenance.

Rotation frequency for thick workpiece machining

If the total thickness of the processed material exceeds 40 mm, the stroke of the molybdenum wire in the processing area will become longer, its jitter will intensify, and the conductive block will wear faster. Faced with such a situation, the conductive blocks must be adjusted more intensively. Generally, after 3 to 4 hours of continuous processing, the conductive block should be rotated by an angle for the first time.

After 8 hours of processing, the second rotation adjustment is carried out. After that, a pattern appears: every 8 hours of processing, a rotation adjustment is performed. This high-frequency maintenance ensures that when processing thick materials for a long time, the conductive block always provides relatively smooth support, significantly reducing the probability of wire breakage.

Control the overvoltage of the conductive block and molybdenum wire

The conductive block is not pressed tightly against the molybdenum wire wire cutting aluminum parts, and the conductive block wears out . An appropriate amount of interference must be maintained between the two. Experience shows that it is ideal to control the overpressure within 0.5 to 1 mm. This gap ensures stable electrical conductivity while minimizing unnecessary mechanical friction.

If the amount of overvoltage is too large, it will accelerate the wear of the conductive block and increase the resistance of the molybdenum wire when running; if the amount of overvoltage is too small, it may lead to poor contact conditions, resulting in electric sparks that will burn the molybdenum wire. Operators need to perform regular inspections using feeler gauges and calibrate this distance to keep it within the optimal range.

How to use the conductive block by rotating it on all sides

![图片[2]-Solutions To The Easy-to-break Wires Of Wire-cut Aluminum Parts-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/01/1768738311554_1.png)

To use the systematic "four-sided rotation method" to improve the utilization of a single conductive block, first use the first surface of the conductive block until three obvious cutting groove points appear on the surface. At this time, rotate the conductive block 90 degrees to enable the second intact surface.

By analogy, after the second surface becomes worn, continue to rotate it and use the third and fourth surfaces. Through this, a conductive block is equivalent to four uses, significantly extending its service life and saving consumable costs. This is a practical technique often used in workshops to reduce costs and improve efficiency.

Gasket adjustment and molybdenum wire diameter monitoring

If all four sides of the conductive block are used up, you can also use spacers to make final adjustments. On the side of the conductive block close to the machine tool sampling line, insert a metal shim with a thickness of 1 to 2 mm, which will shift the entire conductive block to one side, which is equivalent to obtaining a new contact working surface.

When carrying out all the above maintenance, it is necessary to simultaneously monitor the molybdenum wire diameter. For example, after processing multi-layer aluminum plates, the molybdenum wire may be worn from 0.18 mm to 0.125 mm. If the discharge gap compensation value is not modified in the machine tool control system in time, the dimensional accuracy of the workpiece will be out of control, resulting in batch scraps.

In actual wire cutting operations, have you ever encountered other similar situations where big problems have occurred due to the negligence of small details? Welcome to the comment area to share your experiences and lessons learned from it. If you think this article is helpful, please like it to support it!

暂无评论内容