China’s high-strength aluminium alloy riveting and welding processing: a global leader in technology and strength

In the modern industrial sector, which seeks lightweight, high strength and excellent performance, theHigh strength aluminium alloyIt has become an aerospace, rail transport, new energy vehicles and high-end equipment manufacturingcore material. Whereas transforming such materials into reliable structural components.Riveting and welding (riveting and welding) processing technologyis particularly critical. In this area, theChina has risen to global prominence as a processing centre with its deep manufacturing heritage, continuous technological innovation and competitive supply chain advantages.

Why choose high strength aluminium alloys?

Excellent strength-to-weight ratio: Significantly reduce overall weight and improve energy efficiency and performance (e.g. aircraft fuel efficiency, vehicle range) while maintaining structural strength.

Excellent corrosion resistance: Especially in aerospace and marine environments, it is effective in resisting environmental erosion and extending service life.

Good workability and formability: Facilitates the manufacture of complex structural parts by riveting, welding and other processes.

Excellent electrical and thermal conductivity: Suitable for parts that require heat dissipation or conductivity.

Riveting and welding: a key process for joining high-strength aluminium alloys

![图片[1]-China’s high-strength aluminium alloy riveting and welding processing: a global leader in technology and strength-Dalian Fuhong Machinery Co., Ltd](https://endlfh.com/wp-content/uploads/2025/07/QQ20250706-201203-800x646.png)

The joining of high-strength aluminium alloys is the core challenge for their application. Chinese manufacturers have accumulated extensive experience and reached international advanced level in the following key riveting and welding processes:

Advanced welding technology:

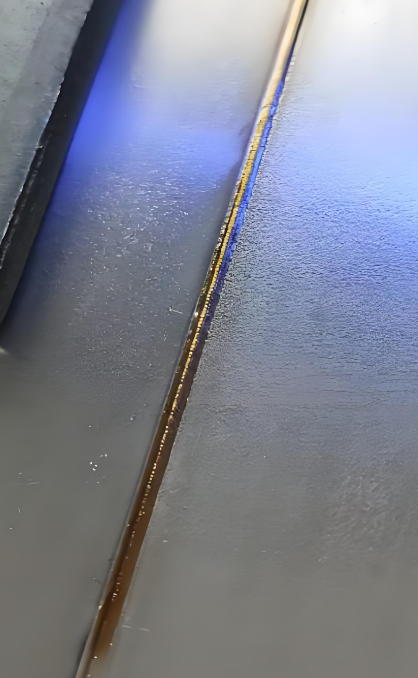

Friction stir welding: Particularly suitable for high tensile aluminium alloys (e.g. 2xxx, 7xxx series).solid connectionAvoid melt welding defects, high joint strength, low distortion and low residual stress. Widely used in aerospace fuel tanks, rail car bodies, etc.

Laser welding and laser-MIG composite welding: High energy density, precisely controlled heat input, fast welding speeds and low distortion make it suitable for precision components and efficient production.

Variable polarity TIG/MIG welding: It effectively breaks the oxide film on the surface of aluminium alloy and obtains high-quality weld seams, which are widely used in aerospace maintenance and other fields.

Precision resistance spot welding: Used for thin plate joining with high efficiency.

Precision riveting technology:

High-locking bolt/ring-groove rivet installation: Providing extremely high tensile and shear strength, it is the main mechanical connection for aerospace structures. The Chinese manufacturer has professional automated installation equipment and strict process control.

Core-pulling riveting: Suitable for one-sided operation in a variety of types (e.g. open, closed, structured).

Press rivets (press-in fasteners): Provides a smooth and even surface for areas with high appearance requirements.

Core strengths of high-strength aluminium alloy riveting and welding processing in China

Powerful knowledge base of materials and processes: In-depth research on the weldability and riveting characteristics of domestic and imported high-strength aluminium alloy grades (e.g. 7075, 2024, 6061-T6, 5083-H116, etc.), and the development of optimal process solutions.

Clusters of advanced manufacturing equipment: A large amount of investment has been made to introduce top international automated FSW equipments, high-precision laser welding systems, robot welding workstations, CNC drilling and riveting systems, etc., to guarantee the processing precision and efficiency.

Mature supply chain and scale effects: From the supply of high-quality aluminium alloy raw materials to the processing of precision components and surface treatment (such as anodic oxidation and spraying), we have formed a complete and efficient industrial chain.Significant cost reductions and shorter lead times.

Strict quality control system: International aviation quality standards such as ISO/AS9100 are generally adopted, and advanced NDT testing methods (X-ray, ultrasonic, penetration testing, etc.) are equipped to ensure the reliability of each connection point.

Continuous technological development and innovation: Universities, research institutes and enterprises have been working closely together to continuously overcome the connection problems of new materials and structures, and to promote process upgrading.

Significant price/performance advantages: The comprehensive cost competitiveness of Made in China is outstanding under the premise of ensuring international first-class quality.

Core application areas![图片[2]-China’s high-strength aluminium alloy riveting and welding processing: a global leader in technology and strength-Dalian Fuhong Machinery Co., Ltd](https://endlfh.com/wp-content/uploads/2025/07/QQ20250706-201356.png)

Aerospace: Aircraft fuselage frames, skinned wall panels, fuel tanks, seat rails, engine component connections.

Rail transport: High-speed rail/subway car body structure (side walls, roof, floor), bogie parts, interior mountings.

New Energy Vehicles: Battery pack casing, motor casing, body structure parts, chassis lightweight parts.

High-end equipment: Robot arms, precision instrument mounts, special vehicle structures, ship superstructures.

Key Considerations for Selecting Chinese Suppliers

Specific alloy and process experience: Confirm its success with the specific material used in your project (e.g. 7075-T6 welding).

Level of technical capacity and equipment: Examine the sophistication and capacity of the core equipment (e.g., FSW, laser welding) they have.

Quality certification and testing capabilities: Essential international quality system certifications and full NDT competence are the foundation.

Engineering support capacity: Ability to provide full process support from design optimisation (DFM), process simulation to pilot validation.

Production scale and delivery guarantees: Assess its ability to meet volume requirements and emergency deliveries.

Awareness of intellectual property protection: Ensure that the cooperation is safe and secure.

reach a verdict

China has built up a reputation in the field of high-strength aluminium alloy riveting and welding processing.Leading technology, excellent equipment, high quality, rapid response, superior costcomprehensive strength. Whether it’s a complex aerospace structure or a new energy vehicle component seeking high efficiency and light weight, Chinese manufacturers can provide one-stop solutions from material selection, process development to mass production, making them ideal candidates for global customers looking forCost-effective and highly reliable aluminium alloy structural componentsThe ideal partner.

Explore China’s leading high strength aluminium alloy riveting and machining services today! Get professional advice and quotes, and experience how China Smart Manufacturing can help your lightweighting goals take off.

Core Keywords: China Aluminium Alloy Processing, High Strength Aluminium Alloy Riveting, High Strength Aluminium Alloy Welding, Aluminium Stir Friction Welding, Aluminium Laser Welding, Aerospace Aluminium Alloy Processing, Aluminium Alloy Components for Railway Transportation, Lightweighting for New Energy Vehicles, Aluminium Structural Component Manufacturing, Precision Rivet Welding Services, China’s Manufacturing Advantage, Aluminium Rivet Welding Suppliers, High Strength Aluminium Alloy Joining Technology

暂无评论内容