How to Contact a Rivet Welding OEM in China to Work with Us: A Comprehensive Guide

Finding reliable riveting machining foundries in China is a critical need for many manufacturing companies. As a global manufacturing centre, China is home to many skilled and advanced riveting and welding companies. In this article, we will provide you with detailed information on effective ways to contact and select a riveting machining foundry in China, considerations, and the cooperation process.

I. Understanding China’s Rivet Welding Processing Industry Overview

Before you start looking for a foundry, it is necessary to understand the overall situation of China’s rivet machining industry:

-

Industrial concentration areasDalian, Liaoning is the region with the highest concentration of riveting and welding processing enterprises.

-

Type of business: Ranging from small family workshops to large modern factories, with a wide range of technological levels

-

Certification Standards: Quality factories usually have international certifications such as ISO9001, ASME, PED, etc.

-

material capability: Different plants specialise in processing different metal materials such as carbon steel, stainless steel, aluminium alloys, etc.

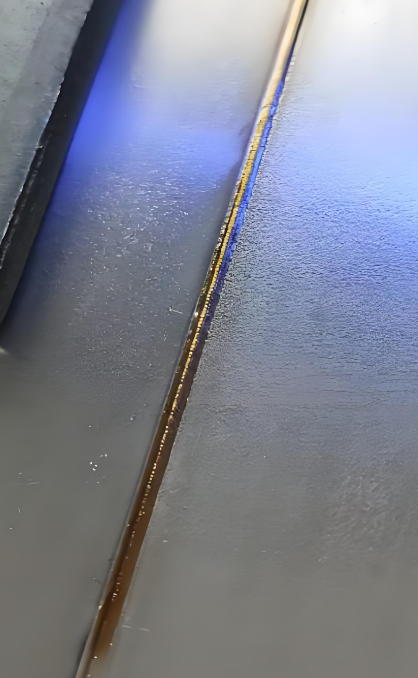

![图片[1]-如何在中国联系铆焊加工代工厂合作:全面指南(在中国寻找可靠的铆焊加工代工厂是许多制造业企业的关键需求) - cndlfh.com-cndlfh.com](https://cndlfh.com/wp-content/uploads/2025/06/QQ20250627-201124-800x496.png)

Second, looking for rivet welding processing OEM factory channels

III. Key indicators for assessing riveting and processing plants

After contacting potential vendors, a critical assessment needs to be made in the following areas:

-

technical capability

-

Welding equipment owned (laser welding, TIG/MIG welding, resistance welding, etc.)

-

Maximum machining size and weight limitations

-

Range of material types and thicknesses that can be handled

-

Engineer and technician qualifications

-

-

quality system

-

Quality certifications (ISO, CE, ASME, etc.)

-

Inspection equipment and processes (X-ray flaw detection, ultrasonic testing, etc.)

-

Control standard of defective product rate

-

Quality Tracing System

-

-

Scale of production

-

Plant area and number of production lines

-

Monthly/yearly capacity data

-

Peak season capacity elasticity

-

-

Case Studies

-

Production experience with similar products

-

Famous Clients Served

-

Areas of industry expertise

-

-

service capacity

-

Design Support Services

-

Logistics and packaging programmes

-

After-sales service response time

-

-

Compliance

-

Proof of environmental compliance

-

Employee insurance and benefits

-

Completeness of tax registration

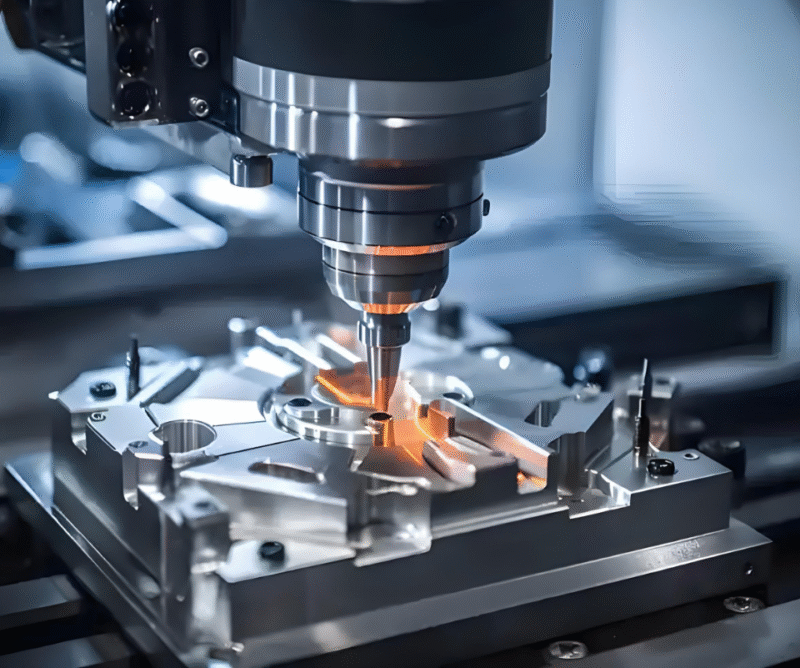

![图片[2]-如何在中国联系铆焊加工代工厂合作:全面指南(在中国寻找可靠的铆焊加工代工厂是许多制造业企业的关键需求) - cndlfh.com-cndlfh.com](https://cndlfh.com/wp-content/uploads/2025/06/QQ20250627-201220.png)

-

IV. Effective communication and enquiry skills

When communicating with potential suppliers, note the following points:

-

Provide clear technical requirements

-

Preparation of detailed technical drawings (preferably in DWG or STEP format)

-

Clarify material specifications and standards (e.g. ASTM, DIN, JIS, etc.)

-

Indicate critical dimensional tolerance requirements

-

Description of surface treatment requirements (painting, plating, anodising, etc.)

-

-

Ask the key questions

-

What is the minimum order quantity (MOQ)?

-

What is the typical lead time?

-

What are the payment terms?

-

How do you handle quality disputes?

-

Are samples available? How is the sample cost calculated?

-

-

Get a comparable quote

-

Get quotes from at least 3-5 factories for comparison

-

Be careful to distinguish between tax-inclusive and tax-exclusive prices

-

Confirm the specific scope of services included in the quote

-

V. Sample verification and small batch trial production

Before formalising the collaboration, it is recommended that the following steps are followed:

-

sample stage

-

Require suppliers to provide samples of similar products

-

Place an order for your product samples

-

Conducting comprehensive inspections and practical tests

-

-

Small batch trial production

-

Ordering small quantities (e.g. 50-100 pieces)

-

Evaluate production consistency and stability

-

Test supplier delivery on time

-

-

On-site Factory Inspection

-

Arranging professional site visits to production sites

-

Inspection of equipment condition and management level

-

Interviews with production managers

-

VI. Notes on the signing of contracts

After identifying a partner supplier, the contract should specify the following terms:

-

Technical terms

-

Detailed product specifications and technical standards

-

Acceptance criteria and testing methods

-

Drawings and design change process

-

-

terms of business

-

Price adjustment mechanisms (e.g., when raw materials fluctuate)

-

Delivery times and compensation for delays

-

Payment methods and billing periods

-

Minimum Order Requirement

-

-

quality assurance (QA)

-

Programme for dealing with quality failures

-

Warranty period and liability coverage

-

Quality penalty clauses

-

-

intellectual property rights (law)

-

Confidentiality agreement for design drawings

-

Mould ownership agreement

-

Product imitation restrictions

-

-

Dispute Resolution

-

Applicable law and competent court

-

arbitration clause

-

Force majeure clause

-

VII. Recommendations for the establishment of a long-term cooperative relationship

Recommendations to ensure smooth co-operation in the long term:

-

Regular communication

-

Establishment of regular communication channels and frequency

-

Regular business review meetings

-

Timely feedback on issues and suggestions for improvement

-

-

Technical Support

-

Provide the necessary technical training

-

Share the latest industry standards and specifications

-

Co-optimisation of production processes

-

-

Order Planning

-

Share production forecasts in advance

-

Rational planning of order tempo

-

Consideration of the impact of seasonal factors

-

-

Relationship maintenance

-

Appropriate visits and factory tours

-

Building Multi-Level Relationships

-

Consideration of strategic cooperation agreements

-

VIII. Frequently asked questions

Q1: How can I judge the true capability of a riveting plant?

A: In addition to checking the certificates and cases, it is best to visit the production site on the spot to observe the workers’ operation proficiency, equipment maintenance status and site management level. You can also ask for recent product test reports.

Q2: How to choose between a small riveting factory and a large factory?

A: Small factories are usually more flexible in price and suitable for small quantity and multi-species orders; large factories are more stable in quality and suitable for large quantity standardised production. Decide according to your order characteristics and budget.

If you are in need of this you can try to contact the website customer service, ready to answer any questions you may have!

暂无评论内容