What does industrial CT non-destructive testing mean?

One of the core methods of manufacturing quality control is industrial CT non-destructive testing. This technology allows you to see every detail inside the product like a three-dimensional model without cutting into it, which can directly help factories save millions in rework costs.

The core of the principle lies in three-dimensional reconstruction

The working principle of industrial CT is actually quite easy to understand. That is to use X-rays to move in a circular motion around the object to take pictures. Just like the CT scan in the hospital, the rays pass through the workpiece from different angles. The intensity of the signal received by the detector shows the density difference of the internal structure. Do you understand?

After processing those projection data with computer algorithms and applying online detection technology in precision machining , a complete three-dimensional image can be reconstructed. In 2025, the FDK algorithm used in mainstream equipment can complete data reconstruction within 5 minutes, and the image resolution can reach the micron level. This resolution is enough to see cracks as thin as a hair.

Detection advantages far exceed traditional methods

Compared with ultrasonic testing, industrial CT has absolute advantages for complex-shaped workpieces. For example, in the case of motor bearings for new energy vehicles, traditional ultrasonic waves often lose signals when facing curved surfaces and grooves. However, CT scanning can obtain complete three-dimensional data at one time.

![图片[1]-What Does Industrial CT Non-destructive Testing Mean?-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1771618454788_0.png)

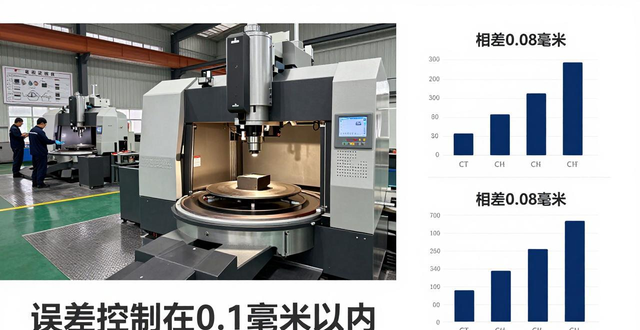

In terms of defect positioning accuracy, industrial CT can control the error within 0.1 mm. In March 2025, there was a precision casting factory in Zhejiang. Its data showed that the difference between the internal pore positions discovered after using industrial CT and the results of traditional destructive testing was only 0.08 mm.

Cost savings from real factories

There is a factory in Suzhou that is engaged in the production of precision bearings. After the introduction of industrial CT in 2025, the rework rate of the factory's products has been directly reduced from the original 15% to 9%. The significance of this phenomenon is that it can reduce about 300 defective products every month. Calculated based on the cost of each defective product being 200 yuan, 720,000 yuan can be saved in one year.

A more critical point is that the scrap rate has dropped by 25%. In the past, there were a certain number of products. In the past, these products were directly discarded because it was impossible to determine the depth of internal defects. Now, CT can be used for precise positioning. By relying on this method, it can be determined whether the defects are within an acceptable range. What does industrial CT non-destructive testing mean? This greatly reduces unnecessary scrapping.

Key points of operation determine the success or failure of detection

The key first step in industrial CT inspection is parameter setting. When testing aluminum alloy parts, the voltage is generally set in the range of 120 to 150 kV. However, for steel parts, the voltage must be increased to more than 200 kV. The exposure time must also be adjusted according to the wall thickness. 0.5 seconds for thin-walled parts is sufficient, while thick-walled parts may require more than 5 seconds.

The operation of software is also of equal importance. Inspectors must be proficient in professional software such as VGStudio or Avizo to carry out defect segmentation and size measurement. Data from an inspection center in Shanghai shows that experienced operators can increase the accuracy of defect identification to more than 98%.

Equipment investment and maintenance costs are not low

![图片[2]-What Does Industrial CT Non-destructive Testing Mean?-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1771618454788_1.png)

The price of micro-focus industrial CT equipment used daily for related testing is generally in the range of 2 million to 5 million yuan, and what it covers is only the basic configuration. In 2025, there is a mold factory in Guangdong purchasing a high-precision CT system worth 4.5 million, which also includes the costs of subsequent installation and commissioning and personnel training.

A situation where ongoing investment is necessary for routine maintenance. Radiation source calibration should be carried out every six months, and detector sensitivity testing must be carried out every year. These maintenance costs generally account for about 5% of the original value of the equipment. However, for high-end manufacturing companies, this investment is still relatively cost-effective compared with the losses caused by quality accidents.

Technological development brings new possibilities

What is changing detection efficiency is AI-assisted analysis. Huawei Cloud cooperated with a testing equipment manufacturer in 2025 to develop a deep learning model. This model can reduce the defect identification time from the original 2 hours required for manual analysis to 15 minutes, and the accuracy rate has increased by 12 percentage points.

The application of portable CT online inspection technology in precision machining has also begun to enter the field of on-site inspection. Just like the in-service inspection of wind turbine blades, in the past, they had to be dismantled and transported back to the factory. Now, with the help of miniaturized CT systems, it can be completed directly at the wind farm, which greatly reduces the cost and cycle required for inspection.

Has your company started using industrial CT for quality inspection? Welcome to share your experience or problems encountered during application in the comment area. Like and forward it to let more people know about this detection technology that has changed the manufacturing industry.

![图片[3]-What Does Industrial CT Non-destructive Testing Mean?-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1771618454788_2.jpg)

暂无评论内容