5 things to note when designing hardware stamping molds

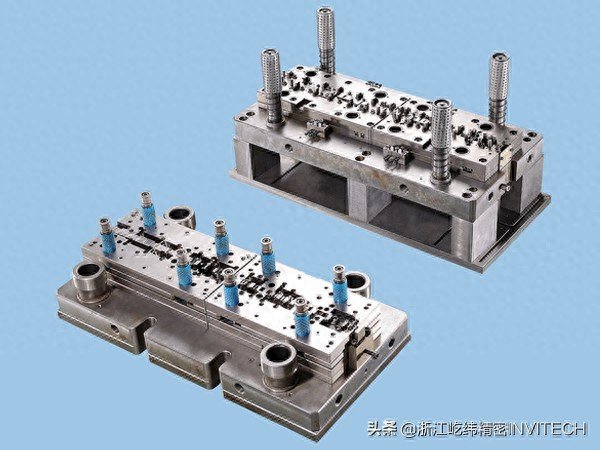

Once upon a time, the design accuracy of a stamping die was 0.1 mm 20 years ago. It has now increased to 0.005 mm, but its lifespan has been increased by 3 times. The reason for this is not something mysterious and mysterious, but a systematic evolution of the mold industry forced by the situation. New energy vehicle structural parts have put forward "micron-level" requirements for dimensional tolerances . Key points in the design of hardware parts processing molds . The cost of raw materials has increased by 15% in a year. The designers of the hardware stamping factory realized that if they continue to use the drawing habits of five years ago, it will be like laying hidden dangers for the workshop.

Data granularity determines device matching

In 2025, a stamping parts factory in Zhejiang received an order for a new energy battery pack mold. As usual, the designers selected the parameters of the existing mold to fine-tune it. However, during the first mold trial, the continuous mold was placed on a 300-ton punch press. , the mold guide post experienced an abnormally high temperature at just over 40 punches per minute. The problem was that the design data collection only recorded the mold tonnage and closing height, but completely ignored the table deflection and deformation data of this customer's punch machine.

![图片[1]-5 Things To Note When Designing Hardware Stamping Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770927015518_0.jpg)

The compatibility of molds and equipment is not something that can be shouted out, but calculated. Nowadays, before leading companies design metal stamping molds, they will require equipment suppliers to provide dynamic rigidity curves, the fluctuation range of slider motion accuracy, and even anchor bolt pretightening force data. At the beginning of 2026, a mold factory in Ningde built an equipment database and entered all the parameters of 87 punch press models from cooperative customers. Before sending the drawings, it first used virtual assembly to run an interference test.

![图片[2]-5 Things To Note When Designing Hardware Stamping Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770927015518_1.png)

Manufacturability is more than just a process issue

There is a precision stamping factory in Suzhou that once designed the carbide insert of a certain automotive connector to be too thick just because of its pursuit of mold life. As a result, during the heat treatment, the internal tissue stress could not be released. After being put online, the whole piece cracked after less than 20,000 times. This is not because the material itself is not good, but when designing, it was not considered that the depth of the cooling oil tank in the heat treatment workshop is only 80 centimeters.

It is not enough to only understand the strength and hardness of the material. You must also understand the burr direction of the supplier's coil material and the aging compensation value of the slow wire-feeding machine tool in the mold workshop. In 2025, a mold factory in Guangdong directly introduced material procurement standards and heat treatment process parameters into the design specifications, requiring engineers to check the angle formed by the position of the material point and the flow direction of the material fiber before drawing. It is this kind of awe for the processing conditions that makes the success rate of their stamping molds jump significantly from 67% to 91%.

Invisible ceiling of process combination

There are some mold designs that tend to compress the processes of trimming, punching and forming into four stations. They think that saving the length of the mold is equivalent to saving costs. However, in 2024, there is a company in Chongqing that is giving a certain date. When the brand produced the tailgate hinge reinforcement plate, due to the forced merging of processes, there was insufficient space for material flow compensation during flanging at the fourth station. In the end, hidden micro-cracks appeared in all the parts in the entire batch of 12,000 pieces.

It is a process sequence of formation rather than a running list. In mature metal stamping die design, a stress migration path diagram will be attached next to the process layout diagram to mark the displacement trend of the hardened area of the sheet after each process in advance. In the budget cost, we should not just look at how many kilograms of mold steel are used, but also look at the error tolerance space left for subsequent projects in each process. One mold factory in Hangzhou even stipulated that when processes are merged, two or more process verification plans must be submitted together and must be signed by the director of the mold trial workshop.

Process parameters must be calculated to the decimal point

![图片[3]-5 Things To Note When Designing Hardware Stamping Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770927015518_2.png)

There is a stamping parts factory that undertakes the production of backplanes for household appliances. It clearly marked the drawing gap as 1.2 mm on its design drawings, and the mold manufacturing workshop directly processed according to 1.2 mm. However, during the mold trial, all the corners at the bottom of the part were roughened. After some investigation, it was discovered that the nominal thickness of the sheet was 0.8 mm used to calculate the gap during the design process. However, it was never expected that the actual thickness tolerance of the galvanized sheet provided by the supplier had reached 0.04 mm. In addition, the mold expanded due to the temperature rise when it was in high-speed stamping. This 0.04 mm became the last straw that broke the camel's back.

Current stamping forming analysis is not just about calculating static loads. By 2026, the mainstream approach in the industry is to import SPC data of material procurement batches into AutoForm, and carry out simulation iterations based on the actual thickness distribution interval. There is a mold factory in Dongguan that even predicts the fluctuation range of the punching force for each new project, leaving a 10% to 15% unloading force adjustment margin for the mold in advance. It is these paranoia after the decimal point that have become the real driving factor in increasing the mold life from 500,000 punches to 800,000 punches.

The precision of the drawings is achieved through pursuit.

Many designers believe that the tolerance of plus or minus 0.01 marked on two-dimensional engineering drawings is extremely strict. However, a company in Wuxi that is engaged in the production of precision stamping parts for medical devices has key points in the design of hardware parts processing molds . Its customer requested that the contour of the mold forming part be controlled within 0.008 mm. According to the request, the design drawing was clearly marked with data, but the mold master responded "there is no way to do it." Later, he discovered that the designer drew a spatial curve directly on the 3D model. When the 2D engineering drawing was exported, this curve was automatically fitted into an arc with a radius of R2.35 on a certain view.

The accuracy of drawings is not determined by tolerance values, but by drawings, sections, partial enlargements and reference systems. At present, the top mold companies in Suzhou Industrial Park require that all stamping mold drawings must indicate the 3D digital model version number, and any non-circular curves are not allowed. Simplified to approximate arcs or spline curves, they also strongly promote full 3D annotation. Engineering drawings are only used as reference. The processing workshop directly calls the 3D model with PMI information for programming. This respect for details has shortened the mold clamping and assembly time by nearly 40%.

Have you ever encountered an experience where the entire mold needs to be reworked or even scrapped just because of an unnoticed detail in the drawing? Welcome to leave a message in the comment area. The lessons you have experienced may help your peers avoid pitfalls. Like it and forward it so that more people engaged in stamping work can see these practical examples.

暂无评论内容