An overview of the principles of size, screw arrangement and cavity position distribution of various templates of hardware molds

If the size of the template is not determined accurately and appropriately, the mold will be directly scrapped. In January this year, I witnessed it with my own eyes in Hengli, Dongguan. There was a small factory. Because only 80 mm of the design key points of the hardware parts processing mold were left on one side of the mold base, the side impact directly tore the template apart, and all the orders worth 180,000 were lost in their own hands. Dimension is not just a random line drawn when drawing, it is accumulated by real money.

Templates and their main dimensions

![图片[1]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_0.jpg)

The length, width, and height of the template are not determined arbitrarily. The width of the material strip, the type of guide posts, and the tabletop of the customer's punch machine are all indispensable. In November 2025, I saw a set of robot molds in Longhua, Shenzhen. When designing this set of molds, the interference in the Y direction was not calculated, which caused the robot to take a detour every time it fed materials. The beat also dropped from 35 times per minute to 22 times per minute. The boss slammed the drawing on the table on the spot.

![图片[2]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_1.jpg)

The integer must be based on the size of the template, rather than rounding, and the drawing must be based on the 5 mm system at the design stage. For example, if there should be 123 mm left for lifting the material plate to avoid the empty space, then draw it as 125 mm. The extra 2 mm is not a waste, but leaves room for error in processing. There are several Japanese-owned factories in Suzhou. Starting from 2024, all template sizes will be forced to be based on 10 mm, and the material purchase efficiency has increased by 30%.

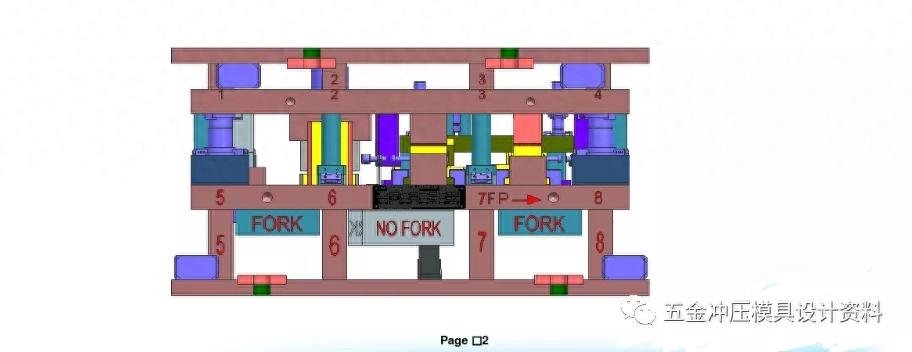

![图片[3]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_2.jpg)

Template thickness standard

![图片[4]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_3.jpg)

If there is a difference in stress, the thickness cannot be consistent. No matter how much clearance the lifting plate has, its thickness will definitely be thinner than the stripping plate. This is not an act of cutting corners, but is based on the rigidity requirements of the structure. In January 2026, I witnessed a set of continuous molds in Taizhou, Zhejiang. The thickness of the stripper plate in that set of continuous molds was 20 mm, which is the design point of the mold for hardware parts processing . Then the lifting plate blindly followed the trend and made the same 20. Unexpectedly, the lifting plate had too much space dug out, so that the strength was not enough, and it deformed when less than 5,000 pieces were produced.

![图片[5]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_4.png)

Blanking force is within the range of hard indicators. If the template equipped with a 315-ton punch press has a stripper plate lower than 25 mm, it is simply seeking death. A hardware factory in Foshan suffered such a loss in 2025. In order to save materials, they changed the stripper plate from 28 mm to 22 mm. The situation occurred. By the third month, the pin holes were simply stretched into an oval shape. The thickness standard is not a reference value, it is completely a red line standard. Whoever saves materials will bear the consequences.

![图片[6]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_5.jpg)

Template design size principles

![图片[7]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_6.jpg)

Regarding the size of the mold, it is not that the more compact the better, nor that the larger the more stable it is, but it depends on what kind of workpiece you are processing and what kind of machine tool you are using. For example, in September 2025, I saw a set of fine blanking dies in Chongqing. Its template was made extremely small. However, it deformed after heat treatment and there was no margin for complementation. As a result, all four boards were scrapped. If the materials were re-introduced, the construction period would be delayed by 22 days.

When designing, the gap on one side should be wider than narrow, the material width should be 150cm, and the mold base should leave at least 75cm on one side. After lifting the material plate to give way and side-shocking the block, it will actually reach 100cm, which is the scope of normal operation. A manufacturer in Ningbo specializes in the production of automobile parts. There are internal regulations that require the vice president to sign when the gap is less than 120. The purpose is to prevent novices from acting blindly and operating blindly.

![图片[8]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_7.jpg)

upper and lower pallets

The length of the pallet usually follows the mold base, and its width is one code mold size larger than the mold base. 120 mm is the starting limit of the industry. In March of that year, a stamping factory in Guangzhou received an order from Italy. The customer's punch press was equipped with a hydraulic automatic clamping die. The support plate was 180 mm wider than the die base to leave room for installation of sensors and cylinders. If you don't leave this amount, the equipment will not be able to recognize the mold, and the automatic mold changing system will directly sound an alarm.

![图片[9]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_8.jpg)

Some customers specify even the pallet chamfer as R20, not for good looks, but because the raceway in their workshop is narrow and the right-angled pallet cannot fit through it. In 2024, a supplier in Jiangsu failed to widen the pallet according to the customer's requirements, so the goods could not be installed after they were delivered to the site. So, someone was sent overnight with an angle grinder to make modifications. The round-trip freight and the loss caused by the downtime totaled 60,000 yuan.

Upper and lower mold bases

![图片[10]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_9.png)

Let’s talk about the single-side clearance of the mold base first. I usually add 150 to 250 to the width of the material strip as the base value. Then let’s talk about the ball guide pillar, which is one circle thicker than the outer diameter of the bare guide pillar. Next, let’s talk about the mold base. The mold base does not enlarge, so the guide bush cannot be inserted at all. Then I mentioned that in August 2025, I was debugging a set of new mold hardware parts processing mold design points in Shandong. The mold base left a size of 190 in the design drawing. As a result, the flange edge of the guide pillar squeezed into the inner guide bushing. After it was forcibly installed, the mold opening resistance was very high, and it could only run 18 times per minute.

![图片[11]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_10.jpg)

When designing the robot mold, it is necessary to make a design that goes against conventional wisdom. The guide pillars are arranged in the inner direction of the product, and the mold base is located at the edge. The closer to the product, the better. Honda's supporting factory made changes to a set of molds in 2024, moving the guide pillar to the inside of the product. The Y-direction length of the robot was shortened by 70 mm. A single cycle can save 0.3 seconds, and the production capacity can be increased by 2,000 products in a day. This is not a showy display of technology, but a real optimization measure that can be converted into money.

Intensity effect

For the same set of molds, the thickness of the punch holder is enough to reach 25 mm, but the unloading plate must be more than 30 mm. Because the stress conditions are different, the thickness cannot be treated vaguely. There is a mold factory in Hebei. In May 2025, in order to reduce costs, it cut the unloading plate from 32 mm to 27 mm. When the production quantity reached 20,000 punches, oil leakage began to appear at the root of the screw hole. When it was disassembled to check the size of the various templates of the hardware mold, screw arrangement and cavity position distribution principles, it was found that the template had been pressed out with a dent with a depth of 0.15 mm.

This lifting plate has so many holes for shelter, but it still dares to be so thin? At a technical exchange meeting held in Chengdu in 2024, someone shared that their company increased the thickness of the lifting plate from 22 to 25, while the gap remained unchanged. As a result, complaints about formwork deformation dropped by 80%? There are 3 millimeters more iron, but in exchange for 120,000 less after-sales expenses per year, even a primary school student can calculate this account.

![图片[12]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_11.jpg)

In the years you have been in this industry, have you ever had a template that needed to be reworked or scrapped due to inaccurate size calculations? In the most serious case, how much money did you lose? Welcome to express your opinions in the comment area so that friends who are just getting started can learn from it and increase their knowledge. If you think this article is of practical value, can you like it and share it with WeChat Moments? One day in the future, when your boss asks why the pallet is 120mm wide, you can directly forward this article to him for review.

![图片[13]-An Overview Of The Principles Of Size, Screw Arrangement And Cavity Position Distribution Of Various Templates Of Hardware Molds-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770926954958_12.jpg)

暂无评论内容