Detailed explanation of wire cutting principles and processing steps

Why is your mold processing always slower than others and prone to wire breakage? The key core of the problem may be hidden in the discharge gap of wire cutting, which can reach millions of times per second. This seemingly "outdated" but irreplaceable process of wire cutting processing is still the last line of defense in precision machining of carbide and quenched steel. However, few people actually understand how sparks "bite" complex contours.

The essence of electrical discharge machining is thermal erosion rather than cutting

In wire cutting, there is never any physical contact between the cutting wire and the workpiece. During processing, molybdenum wire or copper wire exists as the cathode, and the workpiece serves as the anode. A spark gap as wide as 0.01 to 0.05 mm is maintained between the two. When the pulse voltage breaks down the insulating working fluid medium, the discharge channel instantly accumulates heat as high as 8,000 to 12,000 degrees Celsius.

This temperature has the ability to directly vaporize the metal on the surface of the workpiece. Each discharge will create a tiny pit on the workpiece, and the molten metal particles will be washed away by the rapidly cooling working fluid and taken away. The position of the discharge is precisely controlled by a CNC system. Hundreds of thousands of continuous pulses appear every second, and finally the entire outline of the complete shape is outlined.

Electrode wire is a consumable and a precision tool

Many people think that cutting wire is only a tool for conducting electricity. In fact, it is in a state of wear and tear all the time. The diameter of commonly used brass wire is in the range of 0.1 to 0.3 mm. During discharge, positive ions bombard the surface of the wire, causing the wire diameter to gradually become thinner. The low-speed wire-moving machine tool will continuously update the electrode wire at a rate of 6 to 20 meters per minute to ensure that the processing area is always filled with new wire material.

High-speed wire running relies on repeated use of the same small section of wire, and the loss becomes more and more obvious. The control of wire tension is also extremely important. If the tension is too low, the vibration will be offset, and if the tension is too high, the wire will easily break. Data from a precision mold factory in Suzhou shows that processing errors caused by tension imbalance account for 23% of the scrap rate.

Working fluid is more than just a coolant

![图片[1]-Detailed Explanation Of Wire Cutting Principles And Processing Steps-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770826446527_0.png)

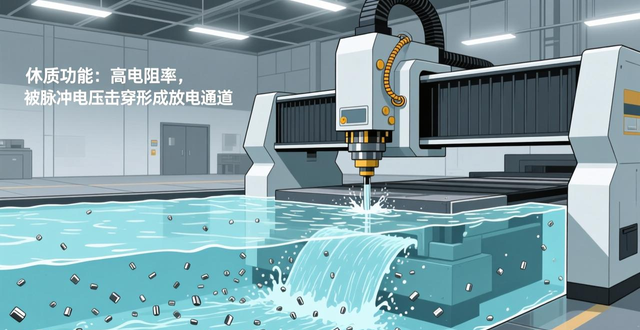

When performing full immersion processing, deionized water or special emulsions have three important tasks. One is the dielectric function. Pure working fluid has high resistivity and can be broken down by pulse voltage to form a discharge channel. The second is chip removal, which uses high-pressure injection to flush the corroded metal particles away from the processing area to avoid secondary discharge.

The third is to resume the insulated wire cutting process . After each discharge, the working fluid must be quickly deionized to prepare for the next breakdown. If the working fluid is seriously contaminated or the flushing pressure is insufficient, the discharge will become unstable and even form an arc and burn the workpiece. The conductivity of the working fluid of slow wire machine tools is often strictly controlled at 10 to 20 microSiemens per centimeter.

Threading is the watershed between automation and manual

When processing a closed cavity, threading holes must be made in advance, and the hole diameter is generally 0.5 to 2 mm larger than the wire diameter. The fully automatic threading system uses high-pressure water and a pneumatic mechanism to push the wire from the lower guide to the upper guide. The whole process takes about 15 to 30 seconds. Some models of Japan's Sodick can even automatically address and re-thread the thread after the wire is broken.

Among small and medium-sized enterprises, manual threading operation is still more common, that kind of manual threading operation. The operator needs to use a magnifying glass to pass the metal wire as thin as a hair through the starting hole of only 0.2 mm. As long as the hand shakes just a little, it is very likely that all the previous efforts will be in vain. A master who has been engaged in related work for 20 years said that it takes at least two years to train a technician who can independently deal with broken wire threading situations.

Broken wire monitoring and process parameter symbiosis

The direct cause of wire breakage is unstable discharge state, excessive energy, poor chip discharge, or excessive wire wear. These situations will lead to instantaneous arcing. Modern machine tools are generally equipped with audio sensors or high-frequency voltage monitoring modules for wire cutting processing . Once an abnormal discharge waveform is detected, it will retreat within 0.1 seconds and reduce the power.

![图片[2]-Detailed Explanation Of Wire Cutting Principles And Processing Steps-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770826446527_1.webp)

![图片[3]-Detailed Explanation Of Wire Cutting Principles And Processing Steps-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770826446527_2.png)

Rely more on pre-parameter matching to prevent wire breakage. The pulse width, interval and current settings are completely different when processing 10 cm thick quenched steel and cutting 2 mm carbide. Practical experience shows that when the thickness of the workpiece exceeds 80 mm, the pulse interval must be increased by 15% to 20%, otherwise the heat accumulation effect will cause the wire to melt like a fuse.

A game with precision control at the micron level

The contour accuracy of wire cutting does not only depend on the machine tool screw. Fluctuations in the discharge gap will change the processing dimensions. Changes in water temperature will affect the processing dimensions. Changes in indoor temperature will also cause changes in the processing dimensions. Constant temperature workshops need to control the temperature at 20±1 degrees Celsius, which is the most basic necessary condition. Some precision mold workshops even carry out circulating constant temperature treatment measures for working fluids.

![图片[4]-Detailed Explanation Of Wire Cutting Principles And Processing Steps-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770826446527_3.webp)

Calculating the compensation of the wire path is equally complex. Because the discharge gap exists objectively, the programming trajectory must be offset by half the wire diameter inward or outward with a unilateral discharge gap. For molds with taper-cuts, it is necessary to add synchronous interpolation algorithms with different shapes up and down. These calculations, which are difficult to see intuitively, are the key factors in whether the finished product can be assembled and matched with the mold at one time.

When you are in a workshop that processes carbide or thin-walled workpieces with sharp corners, the most common problem you encounter is frequent wire breakage or unstable dimensions? Welcome to the comment area to share your own practical cases and corresponding solution ideas, and please also forward this informative content to those colleagues who are still using the "test knife method" to adjust parameters.

![图片[5]-Detailed Explanation Of Wire Cutting Principles And Processing Steps-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770826446527_4.webp)

暂无评论内容