What is the reason why the wire cutting aluminum damages the conductive block? How to solve it?

When the wire cutting machine is processing aluminum alloy, the conductive block wears out quickly. The conductive block wears out when processing aluminum parts through wire cutting , and it is easy to get stuck and break the molybdenum wire. This is a common problem that many operators have a headache. It will not only increase the cost, but also have a serious impact on the processing efficiency!

Aluminum oxide abrasives cause abnormal wear

When wire cutting aluminum alloys, a large amount of aluminum oxide particles will be generated. These particles are extremely hard and are equivalent to natural abrasives. When the molybdenum wire carrying aluminum particles quickly passes through the conductive block, it will produce a strong grinding effect on the surface of the conductive block.

In a short period of time, the contact parts of the conductive blocks will be ground into obvious deep grooves, which changes the conductive contact position and wears out the conductive blocks of wire-cut aluminum parts . More importantly, the hard particles are mixed with softer aluminum chips, which can easily block the grooves and wear out the conductive blocks of wire-cut aluminum parts , laying hidden dangers for subsequent processing.

Increasing discharge and debris clogging issues

Containing aluminum oxide particles may also cause spark discharge. Aluminum oxide itself has insulating properties. When it is sandwiched between the molybdenum wire and the conductive block, it will cause poor contact and form an intermittent discharge phenomenon. This discharge will further cause electrical corrosion of the conductive block material and accelerate its loss.

The more serious problem is clogging. The ground grooves can easily be filled with a mixture of aluminum chips and alumina. Once the grooves are "completely filled to the point of being impassable" by these substances, the molybdenum wires during operation will be tightly stuck. If they are forcibly pulled, it is very easy to cause wire breakage, and the process of dealing with this is quite troublesome.

Common phenomena of similar materials

This problem is encountered when processing aluminum alloys, and it's not the only one. For other conductive materials such as copper and brass, the conductive block will also wear out relatively quickly during cutting. This is because during the processing of copper, hard particles such as copper oxide will be produced.

There are some special conductive ceramic materials, such as silicon nitride or boron nitride. Although they can be used to make wear-resistant parts, when they are processed by wire cutting, the debris generated is also abrasive and will cause similar groove wear on the conductive blocks.

Optimize electrical parameter setting strategy

An effective way to reduce wear is to adjust the electrical parameters. For materials like aluminum alloy, you can try to reduce the pulse width. When the energy of a single pulse decreases, the discharge pits will become smaller, and the size and quantity of the produced aluminum oxide particles will also decrease accordingly, thus directly reducing the grinding of the conductive block.

At the same time, moderately increase the pulse gap time. In this way, the working fluid can be given more sufficient chip removal time, which will help to take aluminum chips and particles away from the cutting area, and help reduce the accumulation near the conductive block, thereby maintaining the stability of the processing and preventing wire breakage caused by poor chip removal.

Maintenance working fluid and conductive block

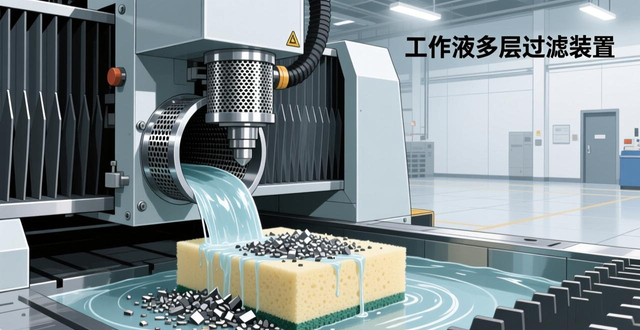

![图片[1]-What Is The Reason Why The Wire Cutting Aluminum Damages The Conductive Block? How To Solve It?-Dalian Fuhong Machinery Co., Ltd](/wp-content/uploads/2026/02/1770725719668_1.png)

It is extremely critical to ensure that the working fluid is clean. It is recommended to add a filter device to the return port and place a sponge at the outlet to perform a multi-layer filtration operation. This can effectively absorb and isolate metal debris and abrasive particles in the liquid. Once the working fluid becomes dirty, it should be replaced immediately.

Regarding the conductive block itself, a regular inspection and maintenance system must be established. Once you find a deep groove on the contact surface, you should immediately turn the conductive block at an angle and use the unworn surface. If there are too many grooves and too deep, then the conductive block should be replaced with a new one. What is the reason why the conductive block is damaged by wire cutting? How to solve it? , and clean the accumulated debris around it from time to time.

Comprehensive process and material selection

According to the thickness of the workpiece, reasonably select the discharge spacing and molybdenum wire diameter. When cutting thick aluminum objects, choosing a slightly thicker molybdenum wire and matching it with larger pulse energy can obtain a larger discharge gap, which is beneficial to chip removal and improving the stability of the cutting process.

If the cost is feasible, you can consider using working fluid products specially designed for difficult-to-machine materials. For example, some emulsions with high lubricity and strong chip removal ability can be diluted in proportion and used for aluminum processing, which can effectively wash away chips and achieve a balance between efficiency and cost in terms of replacement cycles.

When operating wire cutting machines to process aluminum and other special materials, have you encountered any difficult problems that are difficult to solve, or do you have any unique tips to solve the problems? You are sincerely welcome to share your experience in the comment area. If you think this article is of certain use, please give it a like and support!

暂无评论内容