Summary of common problems and solutions for wire cutting aluminum

When wire cutting is used to process aluminum materials, frequent wire breaks and low efficiency have caused many operators to find it quite troublesome. The characteristics of aluminum itself pose special challenges to conventional processing. Only by mastering targeted methods can efficiency and quality be improved.

The particularity of aluminum processing

There is a relatively soft metal, aluminum, which is extremely prone to oxidation when exposed to high temperatures. In the high-temperature discharge environment of wire cutting, the surface of aluminum can quickly form a hard aluminum oxide layer. This already formed oxide layer is mixed with the fallen aluminum chips, thus forming a major obstacle in the processing process. Not only will they affect the continuity of the cut, but they will also stick to critical components, causing a series of subsequent problems.

The trouble of removing sawdust is another key point. Moreover, the material is soft, and the chips formed during cutting are fine and sticky, making it easy to clump together. If the debris cannot be quickly washed away by the working liquid, it will accumulate inside the slit, hindering the smooth advancement of the molybdenum wire, resulting in short circuits, broken wires, or rough processing surfaces.

Selection and treatment of working fluid

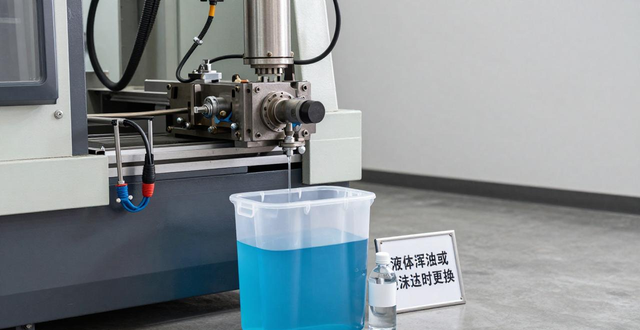

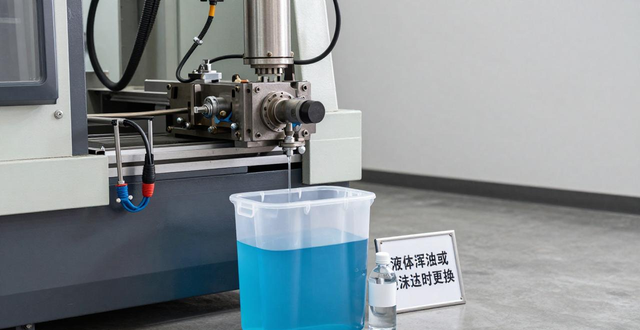

When using conventional concentration wire cutting fluid to process aluminum parts, a large amount of gray dense foam will often be generated. These foams are mainly composed of suspended aluminum chips and alumina particles. They will spread all over the workpiece and workbench, greatly affecting the observation and processing stability . The wear of the conductive block of wire-cut aluminum parts , and the foam layer will also reduce the cooling and chip removal effects of the working fluid.

For this problem, low-concentration working fluids can be used, or even clean water can be used directly for processing. The key is to maintain the cleanliness of the liquid. Once you notice that the liquid has become cloudy or has too much foam, it should be replaced immediately. This method can effectively reduce the generation of sticky foam and improve chip removal conditions. However, attention should be paid to the anti-rust requirements of clean water processing for machine tools.

Wear and position adjustment of conductive block

When cutting aluminum materials, Aluminum chips and alumina hard particles are easily attached to the molybdenum wire. When the molybdenum wire passes back and forth through the conductive block, these hard particles will wear away the surface of the conductive block like sandpaper, quickly grinding out deep grooves. If the molybdenum wire wrapped in aluminum chips gets stuck in these grooves, it may be violently broken.

Regularly adjusting the position of the conductive blocks on the upper and lower wire racks is an effective preventive measure. Do not wait until the conductive blocks are worn into deep grooves before replacing them. Instead, move them to a new contact position before they show obvious signs of wear. In this way, you can always maintain a smooth and reliable contact surface between the molybdenum wire and the conductive blocks.

Optimization strategy of silk transport system

Using the technology of “moving wires to electrify” can change the traditional conduction method. This technology causes the current of the high-frequency power supply to be mainly connected from the conductive device at the end of the wire storage drum, rather than relying entirely on the conductive block on the wire rack. This reduces the current load and wear of the conductive block, and the impact of adhering aluminum chips on current stability is also reduced.

At the same time, it is beneficial to increase the wire speed appropriately. Faster wire transport speed will cause the wear of the conductive block of wire-cut aluminum parts , which will promote the wear of the conductive block of wire-cut aluminum parts stuck on the molybdenum wire . Before it is completely dry and solidified, it will be brought into the conductive block area, which will promote the accumulation of hard particles and reduce the accumulation of hard particles. Flushing with a large flow of cleaning fluid can further maintain the cleanliness of the molybdenum wire.

Targeted adjustment of parameter settings

When processing aluminum materials, the electrical parameters must be moderately “softened”, which can appropriately reduce the pulse width and peak current, and reduce the single discharge energy. Although this may slightly reduce the cutting speed, it can effectively control the high temperature generated by the discharge, reduce the amount of alumina produced and the fusion state of aluminum chips.

The important thing is to increase the pulse interval. What should not be underestimated is that a longer interval can give the working fluid sufficient time to enter the slit, thereby taking away heat and debris, thereby improving chip removal conditions. Compared with pursuing extreme speed and stable discharge state, it can better ensure the success rate and surface quality of aluminum parts processing.

Daily maintenance and operating habits

Before processing, the oxide layer and oil stains on the surface of the workpiece must be carefully cleaned. After processing, the aluminum chips remaining on the workbench, guide wheel and wire drum need to be cleaned up in time to prevent them from hardening and affecting the next processing. Regarding the operating conditions of the guide wheels and bearings, it is necessary to check regularly to see if they are running smoothly. Cleaning work is absolutely essential before and after processing.

During operation, be sure to pay close attention to the ammeter and the status displayed during processing. Once you notice that the current is not stable, or there are abnormal sparks, you must stop immediately for inspection to eliminate the possibility of clogging of the slits in time. Developing good operating and maintenance habits is the most economical and long-term effective way to prevent problems in the aluminum processing process.

Have you ever encountered unique problems when processing aluminum parts? Or are there some efficient techniques summarized from practice? Welcome to share your experience in the comment area and start exchanges and discussions with everyone. If you find this article helpful, please give it a like and support!

暂无评论内容